Cutting plywood on CNC machines - processing of plywood blanks on machine tools with numerical control. CNC machines allow you to manufacture parts in automatic or semi-automatic mode. The advantage of this type of manufacturing lies in the high precision of the actions. CNC processing of plywood can be carried out both in private production and in the factory.

Peculiarities

CNC equipment keeps operator intervention to a minimum. After manufacturing, the part does not require additional processing.

With the help of machine tools, several types of processing can be performed:

- laser;

- milling;

- waterjet.

There is also plasma treatment. But it is used less frequently than other types. Depending on the type of processing, there are both advantages and disadvantages. Their consideration should be given special attention when not knowing which machine is better to choose.

The most acceptable for work are sheet-type materials. Of these types of manufacturing, milling is the most popular. on the machine ensures the manufacture of parts with precise dimensions and smooth edges. Laser cutting is more suitable for cutting plywood.

When cutting, it is necessary to adhere to the rules for using the unit.

With the help of milling, you can create almost all types of parts. Modern models are compact, so they can be placed in a room with a small area. Numerical control provides simple operation. Thanks to this, it is possible to cope with the processing of plywood without any experience. When buying a machine, there is an instruction that describes how to work with it.

Types of milling tools

The most common and functional is the milling type. The design of the machine assumes the presence of a collet clamp. With it, you can use cutters with different diameters with the machine.

Differ in small dimensions. But at the same time they have a lower power rating. Most often, such units are used for additional processing of a part in order to ensure higher accuracy.

There are also waterjet machines. The third type of devices is represented by a vertical base. It has a wide functionality, has a large size. Because of this, the device can only be placed in a room with a large area.

purpose

Giving preference, it is easier to process plywood with a cutter than when using other types of aggregates. The milling device allows the manufacture of parts with complex shapes.

Thanks to milling, it is possible to:

- profiling of cornices, platbands, skirting boards;

- cutting along a contour with a curved line;

- creation of grooves, figured recesses;

- surface decoration;

- drilling holes.

On a CNC router, you can adjust the cutting depth. This feature enables automatic processing. The operator is required to set the trajectory along which the cutter will have to move. If you cut sloppy, the control program will help solve this problem.

Advantages

Milling plywood allows you to get parts with a clean and smooth surface. When using a laser, the edges will be charred and the edge will be burned. To process the ends, additional steps will be required.

Other benefits include:

- the ability to work with material that has a large thickness (thanks to milling cutting, it is possible to process a ten-centimeter thickness, while laser cutting allows you to cope with a thickness of no more than one centimeter);

- creation of curvilinear CNC cutting of three-dimensional products and panels;

- chamfering, rounding, groove milling.

There are special cutters designed for cutting plywood. Using such a cutter, it is possible to produce parts, after which there will be no pile and other defects on the cut.

But laser processing plywood also has a number of advantages. Using a laser cutting machine, you can produce small parts that have precise shapes and fragile elements. Carrying out laser cutting of plywood on the CNC, there is no mechanical load on the workpiece.

Training

Before production, it is necessary to prepare the CNC machine for work. The setup of the unit includes two stages. The first is represented by the setting of tool blocks, and the second - by working mechanisms.

Adjustment is carried out step by step:

- fixing the base and fasteners;

- warming up the mechanisms of the machine tool to ensure stable operation;

- idle running of the control program.

Additionally, you need to check:

- how clean are the system mechanisms;

- whether the drawings and blanks correspond;

- whether there is sufficient coolant and lubricant.

When serial machining with milling cutters, you should carefully monitor the processing of the first workpiece. With its help, it will be possible to determine whether there are errors after commissioning. If there are inaccuracies, additional corrections must be made. If there are several elements, the layout on the sheet saves plywood. After setting up, you will not need to check the control program - it will manufacture parts according to similar parameters.

cutting

Before you start cutting plywood, you need to make sure that the cutters are securely installed in the chuck. To do this, make sure that the cartridge is tightened and the nut is tightened. The check is performed using a wrench.

Then you need to set the depth to which the cutter will penetrate. The limiter knob provides a simple and quick adjustment of this indicator if necessary. To test the milling, it is recommended to use an unnecessary piece of plywood.

Many inexperienced users believe that the larger the cutter I cut, the better. But the principle "cut with a large tool for better work" will not work here. If the cutters have a large diameter, the machine tool should be set to a low RPM. When buying a machine, an instruction follows with it, in which you can see which parameters are optimal for processing.

The dimensions of the plywood blank should not be more than ten centimeters. For the manufacture of larger parts, special CNC machines are used. Professional units allow you to perform three-axis processing and cut thicker plywood. If earlier the operator independently cut the part, now the production is performed automatically. One is required to control the work. Production can be controlled remotely.

Scope of use

Cutting plywood using milling machines is used in the construction industry. Thanks to it, ceilings, wall formwork, foundations are made. Plywood is also used in:

- shipbuilding;

- roofing works;

- laying the floor;

- interior design;

- furniture production.

With the help of milling on CNC machines, figured cutting is created. Thanks to cutting, advertising structures are produced. Plywood has high performance characteristics. The material can be used to make small three-dimensional letters for signs.

Plywood is an inexpensive universal structural material that combines the lightness and warmth of wood, beautiful natural texture, low cost and strength. It lends itself well to milling, grinding and decorative processing. Classified:

Wood species

Birch plywood and plywood made from coniferous wood (mainly spruce) are most widely used on sale. Of all the options, birch plywood remains the top seller in terms of volume. It is popular with furniture manufacturers, in interior decoration, an infinite number of gift and souvenir products are milled from it. It has an even color and a soft, attractive texture. The color of softwood plywood is much darker, the texture is more contrasting. Due to its lower cost, it has become widely used in construction for the manufacture of formwork and other temporary structures. The technologies for milling softwood and birch plywood do not differ.

Impregnation

There are two impregnation options - FC and FSF. Both make plywood partially resistant to moisture and temperature changes, but with some differences. PSF is recommended for outdoor work and contains more resins. FC is the safest impregnation option, contains a minimum amount of resins and is therefore less resistant to moisture. Recommended for indoor use. The type of impregnation has practically no effect on the quality of plywood milling.

Types of processing

According to the type of processing, plywood is divided into sanded and non-sanded. NS - not polished. Ш1 - polished from the front side. Ш2 - polished from the front and back sides. The type of processing practically does not affect the quality of plywood milling.

Plywood grades

The grade indicates the quality of the raw material from which the plywood is made and the number of defects on the visible sides of the sheet. Grade 1 allows up to two defects (inserts) on the visible surface of the sheet. Grade 2 allows up to 8 defects (inserts). In grades 3 and 4, the number of defects increases, knots appear, color and texture become uneven. Usually the grade is indicated by two numbers 2/2 or 2/4. Thus, the grade for the face and the back of the sheet is indicated. Pay attention to an important point - not all grades of plywood are equally well milled. Grades 3/3, 3/4 and especially 4/4 are made from lower quality raw materials. In the process of milling, chips appear on the ends of parts from such plywood, chips can fly off, a lower-quality adhesive layer leads to the fact that parts after milling can delaminate and fall apart. You need to choose low-grade plywood very carefully, only when it is really justified.

Laminated plywood was developed for the production of high-quality reusable building formwork. It is able to maintain properties in direct contact with water, with mortars, concrete. Easily tolerates temperature changes. At the factory, before being pressed and glued, veneer sheets are covered with a special protective layer (laminate). After cutting to size, the ends of the sheets are painted over with paint, which prevents moisture from entering inside. Milling laminated plywood requires more attention and responsibility. Incorrectly selected cutting tool or high-speed modes lead to the appearance of chips. On a dark laminate, they are very visible and cannot be removed.

Cutting plywood is used to create a wide variety of blanks and finished products. The breadth of use of this sheet material is due to its physical, mechanical properties, performance characteristics.

The advantages of plywood include the following qualities:

- resistant to high humidity;

- endures temperature changes;

- does not deform under mechanical loads;

- has a beautiful woody texture;

- has a variety of colors due to the use in the production of different types of wood

Plywood is made from thin sheets of wood called veneer. These layers are arranged symmetrically with respect to the main sheet, glued together with special compounds. For plywood that will be used outdoors, a special moisture-resistant adhesive is used.

A plywood sheet consists of several veneer sheets, which should be an odd number. When cutting plywood, the thickness of the material must be taken into account in order to avoid damage, chips, cracks, and to achieve an even cut.

Most valued are plywood sheets made from birch and oak wood, which have a unique texture and original color scheme. They are used for the production of products for interior design, the creation of exclusive advertising, exhibition structures, and commercial equipment.

For interior decoration in construction, plywood made from coniferous wood is used, which is not inferior in its properties, but has a more favorable cost.

Plywood cutting is one of the technological operations in the manufacture of whole products and structural parts in the following areas of activity:

- indoor and outdoor advertising;

- installation of exhibition pavilions, stands, expositions;

- vehicle finishing;

- design of interiors and exteriors of buildings, structures;

- construction and repair;

- furniture manufacturing;

- production of packaging materials

Our equipment

- The machine is designed for fast feed up to 7400 mm/min.

- The working field of the machine is 2000x4000 mm, which allows the use of large sheets as a whole.

- SHVVP guides.

- Detailed cutting and acceleration settings on the control panel.

- Working sensors for axes and spindle shaft voltage.

Open plywood. Technological features

Sheet processing is carried out in several stages, the first of which is plywood cutting. Technological features of this type of activity lies in the structure of plywood as a sheet material.

Each sheet consists of several layers of veneer. The wood fibers in them can be arranged parallel or perpendicular to each other. When cutting plywood, craftsmen must take into account this property.

If it is necessary to obtain a perfectly even edge of the future cut, the material is cut along the location of the fibers of the top layer of plywood. The resulting blanks, structural details are beautifully joined, look neat and aesthetically pleasing.

In some cases, for example, when creating creative interior decorations, for the original decoration of the premises, it is necessary to obtain the effect of fibrous cuts. Then the plywood is cut across the direction of the fibers of the material.

Of particular importance is the cutting of plywood with a laminated surface. In order not to damage the laminate layer applied to the material, the laminated plywood should be cut to a shallow depth (up to 0.3 mm) with a particularly sharp, thin tool.

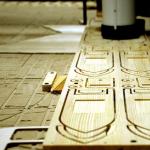

Cutting plywood is carried out under production conditions on special tables, which are an integral part of milling machines. Such tables have dimensions of 2m by 4m and allow you to place a whole sheet of material.

Our company has the necessary modern technological equipment to perform high-quality cutting of plywood in Moscow.

Milling cutting of plywood, price for Moscow and Moscow region

The minimum order amount is 1000 rubles.

In order for plywood cutting to be carried out with a guarantee of quality and in strict accordance with the provided dimensions, the developed layout, milling machines are used. The main cutting element of such a machine is a milling cutter. It moves in a given direction at high speed and performs cutting, sawing plywood quickly and accurately.

Cutting plywood with a milling cutter ensures the accuracy of work, high speed, guarantees full compliance with the dimensions and shape of the future product or workpiece with the specified parameters.

If plywood is cut on a milling machine, the cost of orders is significantly reduced compared to manual processing of the material. The price for sawing plywood on machines also depends on the following indicators:

- sheet thickness;

- order volume;

- layout complexity

Milling cutting of plywood will be cheaper with a bulk order. In our company, there are favorable discounts for cutting plywood in Moscow for regular customers.

CNC cutting plywood

An important function of modern CNC machines is plywood cutting. Equipment with numerical control performs all operations based on commands given by special programs. The machine is connected to a computer, performs work quickly and with the highest possible quality.

Milling plywood using CNC machines allows you to complete orders in the shortest possible time, even with complex shapes of layouts, since the replacement of the necessary tool is done without stopping the equipment. The program itself selects the most optimal version of the cutter, sets it the desired speed, direction of movement, depth of rotation.

Due to the high speed and the number of revolutions of the cutter per minute, it is possible to perform high-quality cutting of plywood up to 70 mm thick. In this case, the cuts are smooth, without protruding fibers. On the surface of the material, even on laminated plywood, cracks and chips do not form.

Order cutting plywood on CNC in Moscow in our company and quickly get excellent blanks, finished products!

Cutting/cutting plywood in Moscow

Plywood cutting is carried out by our company on our own high-performance CNC equipment manufactured by the world's leading manufacturers. The workshop of the company is equipped with machines on which plywood is milled in the shortest possible time. For some orders, we need only up to 1 hour of time!

CNC machines are operated by experienced skilled craftsmen. We guarantee high quality of products, because we use only the best consumables purchased from trusted suppliers.

Cutting plywood with a router. Our advantages

Contact us by phone, email or fill out an online application on the site!