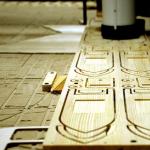

High-quality CNC milling of MDF - precise cutting of cavities of various depths and diameters, processing on external and internal elements that are used in furniture production and at home.

MDF is, in fact, a medium-density fibreboard, which is produced using dry pressing of finely dispersed wood chips treated with a natural binder - lignin (environmentally friendly), under high pressure and temperature.

This material is popular due to its closeness in composition to natural wood, easy processing and low cost. Moreover, experts appreciate MDF boards for moisture resistance and resistance to microorganisms and fungi. That is why CNC milling of facades from MDF is more in demand than from natural wood.

The range of application of MDF

Due to the ease of processing, MDF boards are a very common material in various production areas. In addition to milling, they lend themselves to carving and drilling, they are painted, laminated and veneered. Panels are used:

- for the manufacture of overlays according to the dimensions for armored doors;

- for finishing doors - a pattern is immediately applied to slabs with a thickness of 8, 10 or 16 mm with a milling cutter, and then a coating. Sometimes it is a PVC film with a wood grain pattern;

- for interior decoration of buildings in the form of wall panels;

- in the manufacture of speaker cabinets;

- for the production of MDF facades, elements of cabinet furniture; countertops, wardrobes, design elements for decoration and decor;

- in the manufacture of non-standard parts in shape and size.

MDF board imitating the structure of wood is a lightweight and aesthetic material that has proven itself well during operation. Milling the facade of this material is not difficult for professionals.

Advantages of processing MDF on new generation machines

For the production of work, CNC milling machines are most often used, having processing zones of 3000x2000x300 mm or 2050x1300x250 mm. The use of such equipment expands the range of milling parts, providing high processing accuracy, labor productivity and achieving the highest quality standards.

To perform different operations, various cutters are also selected. Moreover, from various manufacturers in Russia and abroad. The cutter is intended for:

- processing of MDF edges, facades - brazed with hard-alloy plates;

- production of side edges and grooves, removal of edge overhangs;

- manufacture of table edges (one or a whole set);

- single-sided profiling or double-sided edge processing;

- processing of a radius edge and at an angle;

- milling reliefs and gratings;

- processing of the lateral edge of the casing.

Used for 2D and 3D parts processing, it has two desktops - classic and removable, so it is used for all kinds of work. And software control guarantees the highest accuracy of order fulfillment. Work on a machine with numerical control - according to a precisely specified pattern, which eliminates errors and cases of marriage.

Subtleties of the technological process

Today, the use of milling machines has become ubiquitous. And the advantage of the CNC system is that the milling tools are automatically set in motion, obeying the program setting. Since with the help of milling equipment curvilinear cutting of MDF, milling of reliefs, three-dimensional figures and images with high processing speed is performed, the very preparation for these processes becomes more complicated.

Special requirements - for electronic drawings in ArtCAM, AutoCAD, Solidworks and Corel Draw programs (versions 8 to 14), the corresponding extensions.

For curvilinear cutting of MDF and milling of volumetric patterns for facades, a 3D layout is developed, and the files are provided in STL format. In the case of 2D milling, DWG and DXF files are acceptable. This also applies to the option when milled MDF facades are made for the subsequent assembly of cabinet furniture.

Options for manufacturing MDF facade

- With preliminary preparation of blanks in size on a panel saw. It is designed for cutting wood and MDF, which is then subject to milling.

When creating the ArtMaster control program (DeskCNC for imported CNC machines), a number of parameters are selected:

- path and type of instrument;

- type and speed of processing, type of approach to the surface, as well as the speed of cutting into the material;

- tool diameter value;

- opportunities for additional processing.

After its creation, the workpiece must be fixed on the working surface of the milling equipment and directly engaged in milling.

IMPORTANT! When preparing MDF boards for processing, one must not forget to add 3-5 cm on each side for fasteners.

Among the types of fastening of workpieces, a vacuum table, vacuum suction cups and manual clamps are used. And since the milling of a part is often performed with several cutters, their change takes place manually or automatically, which simplifies work and facades are made with 2, 3 and even 4 different cutters.

- Using a CNC router with Nesting technology to optimize the cutting process.

The CNC machining center is capable of cutting, milling, running in and drilling wood-based panels from full-size boards during one working cycle. It is possible to reduce waste to a minimum due to the rational placement of parts. This technology requires a vacuum table and an option for automatic tool change.

In the technological process, straight end mills are used (they are equipped with cutting plates made of polycrystalline diamond), profile end mills and diamond cutters.

Instead of a conclusion

When we mill MDF on machines with built-in software control, we need to purchase the necessary cutters; take care of the presence of a control program, a vacuum table. It is important to ensure automatic change of cutters in order to work with high productivity and supply furniture production with quality components.

CNC milling machines for the manufacture of furniture fronts (straight and curved)

1. Schematic representation of the milling of curved facades on CNC machines

1.1. Milling of a curved facade on a CNC machine with a spindle inclination of + -90 degrees

1.2. Milling of concave facades and straight sections on facades. Straight sections are used for convenient fastening of facade hinges.

1.3. Milling of wave-like facades

1.4. Image of a cabinet with fronts on which straight sections are made

2. Comparison of CNC machines for milling curved facades with and without laser scanning

When pressing facades in a vacuum press, it is inevitablefaçade curvature errors occurdue to uneven drying of the glue, humidity, temperature, and so on

The main problem when milling curved facades: due to the fact that bent facades are obtained with different curvature during manufacture, the milling of the pattern on the facade turns out to be uneven in depth, which can be considered a product defect.

Solution: preliminary scanning of curved facades using a laser rangefinder to eliminate the influence of curvature errors (Option No. 3)

What are the options for CNC machines for curved facades?

Option number 1 - CNC machine with rotary table

Option number 2 - CNC machine with a rotary spindle with a mathematical 3D model of the facade

Option No. 3 - CNC machine with a rotary spindle using laser scanning of curved facades

What problems do owners of machine tools have option number 1 and option number 2

Poor-quality milling on the facade, somewhere there will be a deeper milling, somewhere it will not be, due to curvature errors. You will have to manually modify each facade (sand, putty) to spend a lot of time and effort on this, which will increase the cost of the final product.

Facades with slight deviations from the selected mathematical model will need to be thrown away and the facade bent in the press again

Returns of radius facades from customers, bad reviews from customers due to the poor quality of the drawing of the facades

Option number 1 - CNC machine with a rotary table

The CNC machine with a rotary table only allows processing curved facades from the outside.

The machine does not take into account the facade curvature error., which affects the quality of milling and, accordingly, the quality of the final product. More details about the facade curvature error will be discussed in option No. 2.

This version of the CNC machine for facades is the most limited in use.

On a machine with a rotary table, you will NOT be able to do:

Concave facades

curved fronts

Wave-like facades

Straight sections on curved facades

Option #2 - CNC machine with rotary spindle and mathematical 3D model of the facade

Features of working on a CNC machine:

To mill a bent facade, you need to draw a 3d model of the facade, load it into the PowerMill program and get a control program for the machine (NC) as an output. What should be taken into account that the PowerMill program costs about $ 10,000 (600,000 rubles), and you will also need a specialist to create a 3d model of facades with patterns.

A flat working table is used, on which a tooling is placed, to which a curved facade is attached with the help of vacuum

Then the UE is loaded into the machine and the bent facade is milled

The main problem:

For high-quality milling, a mathematical 3d model must correspond to the curvature of a curved facade, and in practice, all curved facades have curvature errors.

Solution options:

a) try to draw the facade to the turntable of the CNC machine with the help of vacuum, this will work in the case of armrests (since the width of the curved surface is large), but in the case of kitchen fronts, it will not be possible to ideally pull the front under the matrix.

See how well the armrests bend and how badly the facades bend (which means they suck badly) on this video

b) bring into line with the facade - a mathematical model, for this you need to measure the curvature of the resulting facade along its entire length and change the mathematical 3D model for each facade. Long and difficult process.

c) bring it into line with the mathematical model - facade, for this you need to mill the facade (remove shape irregularities) to bring it into line with the curvature of the mathematical model, but in this case the thickness of the facade will be different due to the additional milling performed, and the time spent on such milling will increase the cost of the product. In most cases, milling is carried out with model cutters to a great depth, if the resulting facade has even small irregularities, the resulting pattern on the facade will be uneven.

Conclusions on option No. 2

For such Chinese CNC machines, you need to purchase an expensive PowerMill program (about $ 10,000)

- Armrests can be attracted to the rig using vacuum (preliminary laser scanning of the surface is not necessary)

- Curved facades cannot be completely drawn to the matrix, because of this there are great difficulties with the use of a 3d mathematical model, in fact it cannot be used in mass production and it is difficult for one-time.

Option No. 3 - milling with preliminary laser scanning of the facade surface

Features of work on a CNC machine with laser scanning of facades:

The bent facade is fixed to a special tooling using vacuum suction cups and a small vacuum pump 40 m3/h (similar to option No. 2)

The machine performs laser scanning of the facade and creates a 3D model of a specific facade, taking into account all possible irregularities (using a program developed by our company)

The control program for milling a flat 2D facade that you want to apply to a curved surface is loaded.

Then click on the button "Convert NC to 3D" using a previously obtained 3D facade model the 2D façade is converted to 3D

Automatic milling is carried out

Additionally, you can use our other program to quickly create 2D control programs for facades

Watch this video tutorial on scanning curved facades

conclusions

With a CNC milling machine with laser scanning and appropriate programs, you can quickly and easily mill any curved, concave or undulating facades, taking into account errors in their curvature.

No need to additionally purchase third-party programs for working with curved facades. All scanning programs are written in our company and are unique in their kind, which gives additional advantages in the business of making curved facades.

The use of a rotary spindle +-90 degrees and a work table of 1300x2800 mm allows you to perform many other tasks besides milling curved facades, unlike a CNC machine with a rotary table

3. Four-axis machines for curved facades with a laser rangefinder from the site

With a smooth plywood table (fixing the facades with vacuum suction cups)

With vacuum table (fastening of curved fronts with special equipment on a vacuum table)

Model"G-1328-4s", working area 1300x2800 mm

Model "G-2131-4s", working area 2100х3100 mm

Video of the operation of the CNC machine G-1328-4s with a vacuum table and autochange

4. What options are important for a CNC machine for FLAT AND BENT furniture fronts?

1. Automatic tool change

For facades with a simple design, where only 1 cutter is used, a spindle with a manual tool change is sufficient.

For facades with a more complex pattern, where various milling cutters are used, in order to save time on their replacement and eliminate the human factor, spindles with automatic tool change are used. Automatic tool change is possible only on machines equipped with servo drives (since they have feedback), on machines with a stepper drive, autochange is not installed (there is no feedback on such machines and skipping steps are possible)

2. Desktop type: smooth plywood, PP vacuum or console table

Smooth plywood table:

A straight facade can be fixed with self-tapping screws, clamps or using vacuum suction cups (by connecting a pump with a small capacity)

The curved facade can be fixed to a special tooling using self-tapping screws or vacuum suction cups can be attached to this tooling and the curved facade can be sucked (by connecting a pump with a small capacity)

The plywood table is convenient from the point of view of operation, you can fasten the workpieces with self-tapping screws, clamps, while not worrying about damaging the table when cutting the workpiece “through and through”, since the cost of replacing the table = the cost of plywood 20 mm thick. From this point of view, this table is more convenient than an aluminum table and a plywood table is most often used in furniture production.

Vacuum table and polypropylene:

A straight facade is attached to a vacuum table using a vacuum, if through milling is needed, then a porous MDF sheet is inserted between the table and the facade (through which the facade is sucked). The advantage of a vacuum table over a plywood one is a) fast attachment / removal of a workpiece or several workpieces (saving time) b) uniform fastening of the facade over its entire surface, which has a positive effect when milling at high speeds

The bent facade on the vacuum table is attached with the help of vacuum to a special tooling. The advantage of a vacuum table over a plywood one is a) fast attachment / removal of a workpiece or several workpieces (saving time) b) uniform fastening of the facade over its entire surface, which has a positive effect when milling at high speeds

Console desktop:

The console table with vacuum suction cups allows you to quickly attach / remove the facade using vacuum. Unlike a vacuum table, it is not required to use a powerful vacuum pump (energy saving), and the positioning of the workpieces is carried out using movable traverses and positioners - stops.

3. Laser scanner

For milling "bent" facades, a laser scanner is installed, which automatically calculates the trajectory of the tool, which significantly speeds up the milling of facades. Unique scanning algorithm and our own program for applying a flat pattern on a curved facade, taking into account the facade curvature error

When do you need a laser scanner?

- After the pressing process (which takes place in a membrane vacuum press), the facade takes on a curved shape, but due to technological features, after the glue dries, the radius of curvature of the facade may change slightly, so if you set the mathematical model of the facade curvature once, you are unlikely to be able to mill all curved facades with the same high quality.

- If more than one type of curved facades is used in production, but new types of facades with different radii are introduced. In this case, it is faster and easier to scan new facades and get curvature than to write a mathematical model for each new facade manually.

The photo shows a laser scanner mounted next to the spindle on the Z-axis of the machine gantry.

4. Software

4.1. Our company has developed the Fasad Expert program, which

Designed for quick creation and modification of control programs (NC) for the manufacture of flat facades with rectangular patterns on a CNC machine.

By setting all the parameters of the facade in a tabular form and their quick adjustment - the time to develop or change the existing UE in FasadExpert many times less than with standard creation, changing the UE in the CAM program.

4.2. The program for curved facades with the help of a laser scanner performs

Scanning the surface of a radius facade creates a 3D model of the facade, taking into account its curvature.

Then the operator loads a flat 2d drawing for facade milling, the program combines this drawing with the received facade model, creates a NC (control program) according to which the machine mills a curved facade

CNC machines for milling facades, our company "site" produces in agreement with the customer in various designs.

Full cycle of production of machine tools in Russia: Rostov region, Rassvet settlement, st. Magistralnaya d.7

The company "ArtFrezer" provides services for milling MDF facades in Moscow on CNC machines. MDF is a widely used material based on natural wood shavings. It is widely used in repair and construction due to improved properties and characteristics in comparison with natural wood. In the production of MDF, chips of a certain size are pressed strongly using a binder - usually using urea resins.

|

The finished MDF board retains all the positive aspects of natural wood, but at the same time surpasses wood in a number of indicators due to its increased strength. In addition, the homogeneous structure of the material facilitates the processing, also on CNC milling machines.

Advantages of facade milling

Milling on CNC machines is often used in the production of furniture facades. Skillfully processed MDF boards have excellent properties and are able to transform any room. Similar design options using milled MDF fronts can often be seen in modern kitchens.

A huge number of MDF processing options allows you to create a wide range of designer furniture, increasing its final cost, but at the same time practically without spending money on reconfiguring production. It is enough for a CNC machine to load a vector drawing into the program, set up the system and after a while get the finished product. And since modern machines are capable of simultaneously milling several blanks at once, the speed of production of designer facades for furniture will be enormous, and the cost of the part will only decrease with an increase in the batch.

Milling machines

For milling facades in Moscow, modern equipment is used: ARTISMAN-S3204 CNC machines and equipment similar in quality and production capabilities. Such machines are capable of: milling MDF boards, solid wood and many other materials; to make carving and turning of any complexity; carry out cutting of various sheet materials, including the cut of MDF boards; apply engraving, decorative carving, decorate the treated surface in other ways.

Stages of facade milling

The surface milling work is carried out in several stages, during which corners, surfaces and edges of the required appearance are sequentially created. Depending on the number of cutters used by the machine and the direction of their movement, work can occur in a different sequence.

Milling is not the last stage of work on MDF facades. They are sent to further production, where membrane-vacuum treatment is performed. Next comes the stage of cleaning the surface and puttying, after which the elements of the facades become perfectly even and smooth to the touch. To increase the service life of the surface, a film is stretched from above, which at the same time performs decorative functions.

When milling at the corners of an MDF panel, the thickness of the cutting edge varies from 2 to 10 millimeters, depending on the thickness of the workpiece. When processing corners, the main goal is to remove sharp parts, round corners, give them a more pleasant appearance and prevent chips from further production. Milling the surface of MDF boards used for the manufacture of facades is carried out solely to decorate the surface and improve the appearance of finished furniture.

Photo gallery

|

|

Equipment characteristics

X-Y-Z stroke 600 x 905 x 180 mm. Portal clearance 150 mm. Machining accuracy 0.1 mm/m. Machine size 1300 x 1000 x 930 mm, 275 kg. Supports G-code format, PLT format commands. Any material for processing is possible when using the desired cutter. Polymers: ABS, textolite, fluoroplastic, caprolon, plexiglass, acrylic, composite, fiberglass Metal: aluminum, bronze, brass, copper Wood: birch, beech, MDF, oak, plywood, ash, alder.

The cost of the services provided

Milling MDF in Moscow on CNC. 2 machines with a table size of 2x4 m. The production is conveniently located in the nearest suburbs of Moscow (Moscow Region, Novoryazanskoye Highway, 15 km from the Moscow Ring Road, Lytkarino). New cutters for every order. We work on 2014 prices!

Only 15 km from Moscow Ring Road (Lytkarino)

2 machines with a working table 2x4 meters

Urgent milling

- from 2 hours

Prices for milling MDF

| 3-6 | 39 | 30 | 25 | 20 |

| 7-10 | 45 | 38 | 31 | 23 |

| 12-20 | 54 | 41 | 35 | 26 |

| 21-30 | 77 | 68 | 55 | 38 |

| 38 | 101 | 92 | 79 | 62 |

| Ask an expert: +7 495 789 48 14 | [email protected] |

|

|

Prices for CNC milling MDF in Moscow are indicated in Russian rubles without VAT per linear meter, excluding the cost of the material. The cost is calculated as the sum of the lengths of all cut lines in meters, multiplied by the cost per linear meter for the corresponding material thickness. |

|

Cost of additional services

CNC machines for MDF milling

We mill MDF on 2 new CNC milling machines with desktops 2100x4100 mm. Machine control is fully computerized and is performed by CNC automation. The machines are capable of milling MDF in sheets of any size with an accuracy of 0.03 mm at one time without prior cutting. The machines are equipped with 3 kW water-cooled spindles, which ensure continuous round-the-clock operation without downtime. The spindles generate enough kinetic energy to cut MDF up to 70mm thick at comfortable speeds. The portal and the bed are made of a steel profile 9.5 mm thick, they crush the resulting vibrations. As a result, the cutting tool is fed smoothly, without jerks and vibrations. The additional option Tool sensor sets the spindle to "0" in the Z coordinate, automatically detecting the thickness of the workpiece on the worktable. A nice little thing that saves time in order fulfillment. Both machines are equipped with a chip removal system. We ship clean products.

Milling MDF in medium and large batches

2 CNC routers with tables 2x4 meters allow you to quickly process medium and large batches of material. Orders are executed on two machines at the same time, which reduces the MDF milling time by almost half. The workshop area is 300 m 2 . This allows you to take into operation several eurotrucks of MDF and store large volumes of finished products. Each order is milled with new cutters, we are constantly testing the newest models that improve the quality of MDF milling and reduce the lead time. Unloading and loading of large batches of MDF for milling and finished products is automated and performed by a forklift.

Photo report from production

How MDF is CNC milled

MDF (Medium Density Fibreboard) is a reliable, time-tested material that has gained its popularity:

- - for high strength, which is 1.8-2 times higher than that of chipboard;

- - for human safety - formaldehyde emission at the level of natural wood, which is much less than that of chipboard;

- - for the unique pliability for the cutting tool - in the process of milling MDF, not chips are formed, but dust, which is easily removed from the cutting tool;

- - for viscosity and elasticity - MDF does not crumble during milling, does not chip or stick together.

The special technology of milling "to the radius" allows you to bend the areas thinned out by the cutter and produce radius parts. Milling MDF on CNC milling machines allows you to produce parts with contours of any complexity. This property of MDF is used in the manufacture of furniture facades for doors, kitchen furniture, etc.

In the process of starting milling, MDF does not require any specific equipment settings. The main attention is paid to the selection of the cutting tool and the number of passes. MDF material is very soft and malleable. For this reason, there are always traces of cutter passes on the edge - the fewer passes, the cleaner the edge and less time will be required to prepare parts for subsequent painting. MDF thicker than 22 is very rarely milled in one pass and only with large diameter cutters from 6 mm and above. Keep this fact in mind when preparing layouts.

radius

The thickness of the cutting tool (cutter), depending on the thickness of the material, can vary in the range of 2-12 mm. The CNC algorithm processes layouts in such a way that the cutter does not enter those places where the distance between the cut lines is less than the diameter of the cutter. First of all, this applies to internal corners or parts that are commensurate with the diameter of the cutter. They are left uncut or ignored. This effect is called radius. The difference between the lines of the layout and the trajectory of the cutter in the figure. For this reason, CNC milling is rarely used to make miniature souvenirs. In other cases, MDF milling on CNC machines in terms of price / quality / terms remains unrivaled.

MDF is very popular in the production of custom-made kitchen furniture. When not only the dimensions of the furniture, but also the design of the facade should be individual. The combination of speed modes and milling with cutters with different sections allow you to decorate MDF facades with complex three-dimensional patterns that make each kitchen unique. .

MDF milling is one of the stages of obtaining high-quality durable products and blanks for use in furniture production, in the manufacture of exclusive interior decor items, advertising, exhibition and commercial equipment, and vehicle trim.

According to the structure, MDF is a sheet material made by pressing and gluing wood chips. The plates are perfectly processed, tolerate high humidity, the impact of mechanical stress.

MDF products can be used both indoors for various purposes, and in open spaces.

Milling MDF facades - features

MDF due to its features is an extremely popular material in the manufacture of furniture. Frames, facades of cabinet and built-in furniture are made from it.

Milling of MDF facades is carried out on machines with numerical control, which allows you to perform complex layouts with straight, radius, curvilinear shapes.

Since the plates have a non-uniform texture, it is important to take this feature into account when milling. The program gives the cutter (the main cutting element) the desired speed and speed. Due to the observance of these requirements, the resulting edge of products, blanks is accurate, has no roughness.

CNC milling of MDF facades is performed exactly to the specified depth. This characteristic of the functioning of the cutter allows you to create beautiful images, forms for decorating furniture facades, interior partitions.

MDF is manufactured in several surface options:

- raw;

- laminated

Raw is usually used for the manufacture of internal parts of structures or is subjected to painting and varnishing after milling. Milling MDF with a laminated surface has its own characteristics in processing. To avoid the rejection of workpieces, the appearance of cracks on the surface of the material, special operating modes of the cutter are used, especially durable cutters made of hardened steel are used.

Our equipment

- The machine is designed for fast feed up to 7400 mm/min.

- The working field of the machine is 2000x4000 mm, which allows the use of large sheets as a whole.

- SHVVP guides.

- Detailed cutting and acceleration settings on the control panel.

- Working sensors for axes and spindle shaft voltage.

CNC milling MDF - price in Moscow

The minimum order amount is 1,000 rubles.

Our specialists perform CNC milling of MDF at an affordable and competitive price in Moscow. We offer economically reasonable value to our customers thanks to:

- availability of own high-performance equipment;

- a staff of experienced qualified specialists, taking into account the peculiarities of processing;

- purchasing consumables at wholesale prices from trusted suppliers

The calculation of the cost of milling MDF is carried out when placing an order. This takes into account:

- type of MDF;

- material thickness;

- workpiece dimensions;

- the degree of complexity of the layout

Ordering wholesale batches of products and being our regular customer is profitable! We have developed a flexible system of attractive discounts for them.

Benefits of milling MDF panels with us

Milling of MDF facades, panels and other blanks is carried out on modern CNC machines from the world's best manufacturers. The equipment is operated by qualified employees with a huge positive experience in providing services. We guarantee the excellent quality of each product.

Our work is highly appreciated by customers, as evidenced by the reviews on our website. We are recommended to friends, colleagues, partners.

By agreement with clients, additional services are provided for the development of layouts, delivery and assembly of structures created using CNC milling of MDF.

Place an order and get quality products in a timely manner!