A modern facade solution must solve several problems: to protect the walls of the building from various destructive environmental factors, to give the facade a decent appearance from an aesthetic point of view, and to strengthen it. All these abilities are possessed by modern facade plasters.

Facade plastering

In order to apply facade plaster to the walls, you will need very little: a ruler, a plumb line, a roller to create texture and the plaster itself.

But before proceeding with the main thing, you first need to properly prepare the surface of the walls for finishing works... First, you need to complete all construction or renovation work... Waterproofing, thermal insulation, roofing and framing for various architectural elements buildings must be fully prepared. In addition, it is imperative to clean the wall surface from mortar residues, paint and other possible contamination.

All of these additives contributed to the strength and durability of the plaster. The appearance of a lot of plaster was determined by the color of the sand - or sometimes burnt clay - used in the mix, but often the plaster was also tinted with natural pigments, or the surface was whitewashed or painted after finishing the plaster. Brick dust can provide color, and other dyes not affected by lime, mainly mineral pigments, can be added to the final coating mix. The plaster was also marble or marble - painted to look like stone - diluting the dome oil with water and mixing it with yellow ocher or another color.

The next step is preliminary alignment of the walls. Their curvature should not exceed one and a half centimeters for every two meters. Determining the curvature of a wall is very simple. To do this, a flat bar is applied to the wall and the depth of the depressions is measured with a ruler. If they exceed the recommended values, the walls are pre-leveled with a cement-sand mortar or a special leveling mixture that can be purchased in a building supermarket in the form of a ready-made mixture.

Immediately before application facade plaster, you also need to check the moisture content of the walls. You can check whether the surface needs additional moistening in the following way: moisten a small fragment of the wall with a sponge and observe how quickly the moisture is absorbed into the wall surface.

As the twentieth century progressed, the factory added manufactured or synthetic pigments for some prepared plaster mixes. Many formulations included the use of hair, jute, flax, or straw as fillers. Animal hair gives lime and sand great strength and adhesion; it has long been used as a binder in lime and gypsum plasters.

Ear hair was commonly used, but horse, goat, and even human hair were used as substitutes. However, the use of human hair was rare due to its thinness and weak strength. Examples of external plaster. ... Historical external renderings include a wide variety of aggregates, binders, and reinforcements. Simple classifications include types ranging from very low strength strokes, usually applied in a single thick layer to support a weave or plank, to high strength renderings based on hydraulic cements applied in two or more layers to brick or stone or lime undercoats.

Application of facade decorative plaster

Facade plaster can be applied to walls different ways and a different tool depending on the skills available, the type of specific plaster mix and personal preference, you can use paint spatulas, wide brushes, rollers or any other suitable tool. It is also sometimes rational to apply facade plaster using mechanized means. This is especially beneficial when a fairly large area needs to be trimmed. This reduces the consumption of plaster and significantly saves time for work.

Of course, decorative plaster is applied to walls differently from traditional plaster. As a rule, it is given a special structure that significantly improves the aesthetic qualities of the final coating. But you should decide on the method of application at the earliest stage in order to properly prepare - if necessary, prepare the surface of the walls and purchase the appropriate tool.

So, for example, in order to give the walls a pattern in the form of a scythe, a needle-like surface or to make a so-called bark beetle, a base layer of facade plaster is first applied to the wall using a trowel. Then, when the first layer dries up a little, the next one is applied on top of it. The second layer is processed with a special structured roller, which is made of rubber. It is with his help that the craftsmen achieve the above-mentioned structural drawings on the facade of buildings.

Other types include low to medium strength deposits based on lime applied in two or more layers to support brick, stone, unfired earth, netting or plank; and medium-strength oil mastics, commonly used in a single thin coating of brick, stone or lime, but also used to model parts. Historic exterior plastering includes parrying, sgraffito and marmorino. Treatments and coatings associated with plastering consist of at least a portion of a plastic or malleable material, including weaving and brushstroke and cob.

We build and repair ourselves

Modular block containers

Block containers are a very interesting element in many respects used in the construction of objects of various purposes. Each block container is ...

How to make a ladder

Many owners of country houses are interested in a very important and serious question: how to make a good staircase with minimal costs so that it will last a long time and with high quality ...

These are regional differences in traditional mixtures of mud, clay, lime, chalk, cement, gravel, or straw. A railing is an exterior decorative plaster that is often cut or modeled with decorative prints or designs made with mold or comb. It consists of a tough lime plaster made from lime putty or mixtures of lime and gypsum plaster reinforced with wolf hair, and with a tall oil additive sometimes added as a plasticizer and water repellent.

The surface of the cobweb was poured frequently; sometimes used as a protective coating linseed oil or wax. During the Renaissance, ash-stained lime plaster was used as the bottom layer and then covered with white lime plaster. The lowest leveling layer then usually consisted of Portland cement, over which a layer of cement dyed with earthy pigments was applied. The last layer for interior work was parium cement; Portland cement was used outside. With all materials, the layers were allowed to dry, but not fully set until the design was cut with an iron stylus or knife used to remove the top layer.

Before applying decorative facade plaster "bark beetle", the surface of the wall must be carefully leveled... This process is carried out by applying a cement-sand mortar directly to the wall with a special rule. In order for the walls to be perfectly flat, it is recommended to carry out plastering work using a lighthouse profile, which is fixed to the wall before starting work.

After the plaster or cement has been fully installed, areas of the structure can be oil-gilded. In more open areas, additives such as metallic sand were added. Low-strength wattle and daub consists of intertwining sticks, twigs or branches plastered with clay, grease or dirt. For roofs, walls and fences, especially in the early 19th century, weaving and brushstroke designs were used. Traditional mixes also include mixes of lime putty, sand and slurry cow dung, fortified with chopped straw.

Required tool:

- construction float;

- floor polisher;

- drill;

- malka;

- bucket.

Study in addition to this article.

We plaster the walls along the lighthouses

The distance between the profiles fixed on the wall should be 10 - 15 cm less than the length of the rule... In order for the extreme profile strips to be installed exactly, they are set in level. You can stretch threads between the profiles and install internal beacons along them.

Sequence of works for plastering the facade

Cob - walls made of clay, earth, straw, lime and sand mixed with water. Wet clay or chalk will scare off a horse with a straw or reed. It is built without blinds in layers on a stone or brick plinth. It is pressed against the walls, the surface is cut off as it hardens. It is usually covered with protective linen or plaster. However, it should shed light on the variety of materials and mixtures used over the centuries, and especially in the last two centuries. Their use sometimes gave rise to persistence problems, and now we are faced with the problem of preserving them.

The cement-sand mortar is thrown onto the walls between the lighthouses by hand and then leveled along the wall with a rule that is tightly pressed against the lighthouses. As a rule, after the rule, the plastered surface has recesses and recesses, which must be rubbed with a small or special construction float. To get the work going faster, a floor polisher is usually used.

It is only by knowing for sure that the composition of these materials makes it possible to ensure the survival of the remaining examples. Biscont G. Piana M. and Riva G. A study of limes and intonations of historic Venetian architecture. B: mortars, cements and mortars used in the preservation of historic buildings. Reprinted with additional notes, Society for the Protection of Ancient Buildings.

Materials and Methods in the Decorative Arts Illustrated Dictionary, University of Chicago Press. Artificial marble in the Baroque style - impact on environment, degradation and protection, European community. Single-layer mineral solution for the protection and finishing of facades.

A detailed video instruction on how to plaster the walls of the facade along the lighthouses

We rub the cement-sand plaster

After a few hours after leveling the surface, the wall is rubbed with a floor polisher or float in a circular motion. ... This method will make it possible to remove all errors and flaws that appeared during the plastering process.... If necessary, this technique can be repeated a day later.

The unique product allows the use of an application manual or mechanical projection. For concrete blocks, ceramic blocks, silica limestones and unmodulated concrete surfaces primed with quartzite rolling slabs. Can be applied over plaster. If contact lenses are worn, remove if necessary and continue rinsing. If swallowed, rinse victim's mouth with plenty of water. If you are not feeling well, contact a poison control center or doctor.

- It allows you to adjust, waterproof and clean.

- The final finish in travertine with a touch of the natural beauty of the façade.

- As an architectural solution, 6 different colors are presented.

- On horizontal surfaces that are stressed or saturated.

- On plastic or metal surfaces.

- On plaster, plastics or organic coatings.

- Over waterproofing or materials with low mechanical strength.

- In areas of constant contact with water or in contact with soil.

- Keep containers tightly closed and out of reach of children and animals.

- Seek medical attention if skin irritation or rash occurs.

- In case of contact with eyes, rinse thoroughly with water for several minutes.

- If eye irritation persists, seek medical attention.

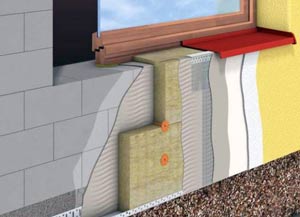

We attach the insulation

The application of plaster "bark beetle" can be carried out on a wall on which extruded polystyrene foam or polystyrene is installed as a heater. In this case, it will be correct to apply glue to the facade insulation material, followed by the application of a plaster mesh on it. Align such a structure with a bevel. The insulation must fit evenly, otherwise you will have to correct the wall drops with plaster mortar.

White cement, lime, light aggregates, additives and pigments. Fill in imperfections in masonry or block joints when they represent a depth, width, or height of more than 20mm. Mix 75% of the amount pure water indicated on the side marking of this package, then powder, and then the remaining 25% water. Add half of the water to the equipment compartment; then add the entire volume of the solution and. complete with the rest of the water. Mixing times may vary depending on the type of equipment and the number of bags and must be controlled by the operator. A new coat can be applied over a period of 12 hours to create decorative details, curtain rods, moldings or imitation of embossed stones. the coating should not exceed 30 mm when applied to brickwork or 25 mm when applied over the previous coating.

- Do not apply on very hot surfaces or when waiting for rain.

- Remove residues and dirt from the substrate before applying the board.

- Use horizontal mixers for 2 to 5 minutes.

- Avoid the formation of lumps in the mixture by homogenizing well. material.

- The panel thickness is 10 mm.

Plaster the wall with a "bark beetle"

To begin with, let's get acquainted with the basic rule of applying plaster "bark beetle". The plaster is applied in an integral continuous layer on the scale of one wall in one step. This will make it possible to dock the freshly applied material with the mortar that has not had time to dry. This technique will allow you to get a monolithic seamless layer of plaster mortar and exclude drops.

Advantages of decorative facade plaster

The product eliminates the phases of plastering, plastering and plastering, one application with a dedicated projection machine, which ensures a good finish and a high speed of coatings. The speed of application depends on the projection directly onto the walls, providing time savings with the same amount of labor. The product makes surfaces more perfect, compact and smooth, which makes painting maintenance easier.

For places where there is no need for final finishing very High Quality, to ensure a satisfactory result, it is sufficient to carry out waterproofing between the designed plaster and the wall paint. How should the procedure be in each case?

A detailed video about applying bark beetle plaster to insulation

Felipe. Project plaster requires the use of a specific projection machine. However, projection is only the first step, followed by manual surface regulation processes, coating uniformity and final smoothing. Projection reduces application time and labor cost. For example, a team of four can complete up to 200 m² of surface area per day. However, the speed of execution is higher if the masonry is of good quality and flatness, as well as good planning and general organization of work.

Felipe - Thickness may vary on one surface. Depending on the flatness of the masonry, we can find large differences between the thickness of the plaster in different areas of the surface to be coated. It is clear that the more irregular the surface, the greater the need for its regularization, which requires more time and more product.

The plaster mixture is mixed in a bucket or other container with a construction mixer, a drill with low speed or a conventional drill, on which the speed is set to a minimum. The dry mixture is poured into pre-prepared water, and not vice versa. If the solution is mixed in a bucket, then water is poured into it by a third of the volume.

Study the material about and find answers to your questions.

What is the formulation of gypsum mortar? Adhesion is carried out directly on the surface without the need for any other treatment. Projected gypsum consists mainly of limestone, gypsum powder and additives that determine, for example, product run time and the level of adhesion to substrates. The product is designated for covering interior walls of masonry, ceramic block or concrete, other than covering slabs and pillars, with a specific projection machine.

Plaster the wall with a "bark beetle"

This eliminates the sanding, plastering and plastering phases. What is the cost of the application per m²? Where should this solution not be applied? The speed of application depends on the projection of the plaster by a particular machine directly onto the walls, which saves time with the same workload. That is, using a projection machine, the installer makes more m² per day, in direct comparison with a manual process by 100%. Already prices vary depending on the region of the country and the quality of the surface that needs to be covered in the work.

The optimal consistency of the ready-to-use solution should resemble mashed potatoes. After kneading, the solution is left for 5 minutes to settle.... Then the plaster is re-whipped. Now that all the lumps are broken and the components are completely dissolved, the material can be used as intended.

Horizontal and vertical application of "bark beetle"

It is generally accepted that the final texture of the surface plastered with "bark beetle" depends on the manufacturer and brand of the product. It is worth noting that this indicator also depends on the technique of applying the mixture by the master.

If it is necessary that the plaster grooves are placed horizontally, it must be applied in the same direction. To obtain vertical grooves, you need to change the direction of application.

By carrying out this process, you can understand and appreciate the whole need for high-quality preliminary plastering. If the cement plaster is applied evenly and well rubbed with a polisher, the relief structure of the "bark beetle" will be clearer. Small pebbles in the plaster mixture create a kind of relief, which form furrows from friction between the wall and the small one.

Spiral application of "bark beetle"

Carrying out in the process of plastering circular movements small on the surface of the facade, you can achieve the effect of a spiral arrangement of grooves, because the pebbles will stretch according to the movements of the tool along the wall. Over decorative plaster can be applied facade paint any shade. Acrylic paint works best here.... All plaster manufacturers advise to paint. But for some time the facade can be left unpainted, there will be no harm to the "bark beetle" from this.