Aerated concrete is a building material that resembles foam blocks in texture, but has certain differences in the composition of air bubbles inside the material.

Due to their porous surface, the blocks have high level moisture absorption. That is why aerated concrete walls outside need finishing work.

Aerated concrete blocks are produced according to a certain technology from cement, the mass fraction of which is about 50%.

Material Features

If we conduct a comparative analysis of foam blocks and aerated concrete, we can notice the following.

Foam concrete in its composition has air bubbles closed and isolated from each other, due to which its moisture resistance increases.

Gas blocks, on the contrary, in structure consist of open bubbles, due to which moisture instantly seeps deep into the material.

Due to this feature, aerated concrete has a lower resistance to heat transfer and resistance to low temperatures, and also requires high-quality finishing of both external and internal surfaces. It is the plaster for aerated concrete blocks that will negate the shortcomings of the porous structure of this finishing material.

When is the best time to treat aerated concrete walls?

Plaster for aerated concrete

Most experienced repairmen start plastering work immediately after the walls are built. When working with aerated concrete, such a rush can play a trick on you and lead to various problems that cannot always be fixed.

Following the advice of the masters, if you are building walls from gas blocks, try to make aerated concrete plaster only in the next season.

If wall decoration is needed immediately after their construction, try to be as careful as possible when choosing a plaster mixture. First of all, pay attention to its elasticity and level of vapor permeability.

The main difference between aerated concrete is the speed of wetting the material, as well as prolonged drying and the inadmissibility of overfilling with vapor and moisture.

For work on the construction of walls from aerated concrete blocks, it is better to start finishing indoors, and only then go outside. This will allow you to do internal work at any time of the year, and outside - in the most suitable weather conditions.

An exception to the rule may be buildings, the construction of which was carried out in places with a high level of humidity (sea or river coast, forest, etc.). Plaster for aerated concrete of such a building is simply necessary, and it is better to complete it as soon as possible in order to protect the walls as much as possible from moisture and other weather disasters.

Of course, it is possible to carry out wall finishing work both outside and inside the room at the same time, but this option is not very preferable if you want to get a high-quality coating.

The main thing in the technology of the process with aerated concrete is the performance of work without haste. After erection, the aerated concrete building must dry thoroughly, and this takes a lot of time.

Wall decoration in the house with plaster

If the plaster on aerated concrete was made with a heavy cement composition, and even on a surface that has not dried out and in the cold season, then when it becomes warm in the room, moisture vapor will begin to move to the outer edges. Due to the low vapor permeability of the plaster mass, they will not find a place to exit and will fall out like condensate, and its freezing will lead to a complete peeling of the plaster layer from the wall surface.

Among experienced builders, there is an opinion that the most inappropriate time of the year for plastering aerated concrete structures is the period between November and March.

Is it necessary to insulate the walls of aerated concrete from the outside?

During the construction of aerated concrete walls, their density is calculated based on the climate.

As practice shows, a correctly calculated coating density does not need to insulate the walls from the outside. Moreover, there are situations when excessive insulation can contribute to the destruction of the structure.

We cover aerated concrete walls with a joke

To insulate the structure, they often resort to the use of expanded polystyrene, which is considered a material with high thermal performance. But, low vapor permeability can lead to the release of condensate at the junction of the insulation and masonry from water vapor, which are released from the blocks of aerated concrete. And their freezing, as we have already said, will lead to nothing more than to the destruction of the building.

That is why you should not choose such a density of walls that will require subsequent insulation. Even thin-layer aerated concrete, due to its thermal characteristics, does not need to build structures of great thickness in order to save heat in the building.

If you nevertheless decide to additionally insulate the walls of aerated concrete using expanded polystyrene, select its density so that moisture accumulation can be avoided. For this, the density of the insulation should not be less than 8 cm, and the thermal resistance should not<50% от общего показателя сопротивления стены.

What mixture is better to plaster gas blocks?

As it may seem at first glance, aerated concrete plaster does not require compliance with a specific technology during the mixing of the mortar.

But, this is far from the case. If you knead the usual composition of cement and sand, in the future you will have small problems that we have already mentioned - when different substances come into contact according to their physical properties, the plaster mass will crack and peel off from the wall.

Aerated concrete plaster must be characterized by high vapor permeability, not be affected by moisture, have good adhesion and a high level of resistance to low temperatures.

- Lime and cement based plaster

Such a light thin-layer plaster has all the necessary properties that are great for aerated concrete work.

An excellent representative of such a substance is Baumit HandPutz, which is made for manual surface treatment.

The main physical features of the lime-sand mortar for the treatment of aerated concrete walls are shown in the table below.

Plastering aerated concrete wall

According to the technology of plastering walls from aerated concrete blocks, it is recommended to apply a spray to the previously cleaned coating, which is part of the plaster mass.

- Acrylic plaster

This solution is used for decorative finishing works. It is characterized by high strength, due to which it is approved for use in any work where particularly durable materials are needed.

Unfortunately, acrylic mixtures are inferior to lime-sand mixtures in terms of vapor permeability, therefore, condensate may accumulate in the layers of walls treated with such a solution. To avoid this, you can use reinforced internal waterproofing of surfaces, or improve ventilation.

Be careful, because acrylic plasters are characterized by low fire resistance, which is why their scope is quite limited.

Bolix is considered a worthy representative of acrylic plasters.

- silicate plaster

The representative of this plaster is Baumit SilikatTop - a paste-like composition, ready for use. Such mixtures are made using a special technology based on potassium liquid glass.

Silicate-based plaster has the following advantages, which are especially important when working with aerated concrete:

- has a high level of vapor permeability;

- has low moisture absorption.

The disadvantages include a small selection of a palette of colors, as well as a loss of appearance due to dust particles settling on the surface.

- Silicone-based plaster

This is another type of plaster mortar, which is often used when working on aerated concrete blocks. This material is made on the basis of silicon and organic polymers.

The advantages of silicone plaster are:

- resistance to weather disasters;

- hydrophobicity;

- high level of vapor permeability;

- ease of application;

- long life cycle.

There are practically no cons to this solution. One nuance that should be emphasized is the high cost of the material, which is why silicone plaster cannot be attributed to the budget option.

Aerated concrete wall plastering technique

plastered walls

Given the fact that the surface of aerated concrete is not characterized by the presence of a large number of defects, chips and cracks, it does not need to use special solutions for leveling, it will be enough to cover the wall with a thin layer of plaster.

Plastering walls from aerated concrete blocks is carried out in 3 steps.

Stage 1 - surface treatment with a primer

This stage consists in covering the wall with a primer mass using a roller or brush, and the solution must be designed specifically for work on surfaces that actively absorb moisture. Cover the walls carefully, avoiding dry areas. When priming is complete, the surface should be allowed time to absorb and dry.

Stage 2 - installation of reinforcement

To fix the mesh on the wall, it is better to use self-tapping screws, and select the reinforcement from fiberglass, which is resistant to alkalis. Given the fact that decorative coatings contain alkaline components in their composition, the mesh must cope with such influence and not lose its coating, which protects it from rust.

Do not forget that during the installation process, an empty space must remain between the reinforcing mesh and the wall.

Stage 3 - finishing work

This is the main process, which consists in plastering aerated concrete. The main thing that needs to be achieved in this process is that the vapor permeability of the plaster is higher than that of aerated concrete.

Among the masters there is an unspoken rule: with each layer, the characteristics of the materials should increase. Therefore, when starting to paint the surface, it is necessary to select only "breathable" paints that freely pass vapors and moisture. You can also use other thin-layer coatings that have the same characteristics.

If you want to additionally protect the walls from moisture, 10-12 months after finishing, they can be coated with a water repellent, which will significantly extend the life of the surface and preserve its appearance for many years.

Renovation inside the premises is carried out in several stages. When carrying out repair work, it is important not to forget about plastering concrete walls from the inside. Plaster for aerated concrete plays an important role, even when it comes to work in modern panel buildings. As a rule, concrete slabs have an uneven surface, and this defect cannot be corrected with putty alone. Block coverage is necessary for a number of reasons. These include the smoothness and cleanliness of the wall surface.

For plastering the internal surfaces of a building, during the construction of which aerated concrete was used, two methods are used. The first method is that plastering on aerated concrete is carried out in such a way as to achieve vapor permeability in concrete walls due to the unique qualities of the material. Builders do not recommend using mortar and cement and sand for finishing blocks indoors. Aerated concrete blocks instantly absorb liquid, after which they become covered with cracks. It will not be easy to mask the irregularities that have appeared even after priming the vapor-permeable wall.

Some specialists are engaged in plastering gas blocks using a different method - vapor barrier. At the same time, the indoor climate will be the same as in reinforced concrete buildings. The only difference is that such plastering will be more reliable.

Promotes vapor permeability of the walls

The components contained in aerated concrete contribute to the vapor permeability of the building material. However, this factor requires the selection of a certain composition of mixtures for repair and finishing work on the walls of the building. To do this, it is necessary to perform plastering in such a way that the inner wall is vapor-permeable or, on the contrary, vapor-proof. In a house with such a wall, the microclimate will self-regulate. In addition, they will not be in the wall.

vapor barrier

To process the inner wall and increase the vapor barrier at least ten times, experts apply a solution, the thickness of which should reach two and a half centimeters. The plaster contains cement and other ingredients. Sometimes, for this purpose, workers put a film of polyethylene under a layer of plaster. But experienced builders are not advised to carry out such work, since the film can peel off plasters and walls due to condensation.

What materials and tools are used?

Everything depends primarily on the task that customers and specialists have set for themselves. For its implementation, building materials are selected that can properly interact with aerated concrete and have the property of vapor permeability. Professionals recommend treating the inner surfaces of the walls of the blocks with a mixture of gypsum, sand and lime. Builders also use tools that include chalk or marble.

For finishing work, specialists use tools for plastering. The mixture is prepared in containers of the appropriate size. The solution is mixed with a mixer either. Thin-layer plaster on aerated concrete is applied to the blocks with a trowel or trowel. Rubbing surfaces is carried out using a grater. A half-ter is used to remove excess mixture. The surface of the blocks inside the walls is leveled with beacons. The aerated concrete plaster is pulled together by the rule between the guides. Builders determine the quality of the work carried out with a rail.

Technology for finishing aerated concrete surfaces

Aerated concrete plaster inside buildings is produced using different technologies. Vapor-permeable finishing works are considered the most common. Plaster walls made of aerated concrete have little difference from traditional finishes.

The subtleties of the workflow

To achieve greater vapor permeability when finishing gas blocks, you can use plasterboard panels. It should be borne in mind that, according to the approved rules, it is impossible to finish the building from the inside with vapor-permeable building materials, and from the outside - with vapor-tight means. The durability and reliability of the finish will directly depend on how high-quality materials are used in construction and decoration. According to experts, even high-quality plaster is unlikely to be fixed on low-quality aerated concrete.

Also, builders are advised to use the following useful tips:

- When driving in nails, the plaster will crumble if there is no wallpaper on the walls. You can avoid this if you apply adhesive tape to the place where the nail will be hammered.

- If the plaster layer lags behind, then it can be further strengthened. It is necessary to drill several holes in the layer, then pour the glue with a syringe and fix the plywood on top.

- Before the plaster solution, it is necessary to drive in a few nails around the perimeter. Such a patch will be more reliable.

One of the most common ways of exterior facade decoration is plaster. If your house is built from aerated concrete, you need to know a number of characteristics for subsequent work on a specific block structure. To understand the meaning of plaster outside, knowledge of the characteristics of this building material is required. After all, the right technology is the best way to increase the durability of the facade, giving it a pleasing look for the eyes of the owner of the house.

During production, aluminum powder is added to aerated concrete blocks, which serves as a blowing agent. The block has a permeability much higher than that of a brick. This structure allows the walls to breathe. With thermal engineering calculation, the thickness of aerated concrete walls is sufficient for our climate. And this means that you can get by with only double-sided plaster without external insulation.

Plastering of the facade can be started only after the interior decoration of the house. If you start work outside during the construction season, and inside after outside work, this will be the biggest mistake in the process. During wet interior work, during evaporation, all moisture will escape, in addition to ventilation, through the walls. At sub-zero temperatures, moisture will remain in the walls. In this case, the plaster will begin to exfoliate and fall off.

It should be taken into account that improperly selected plaster for the facade can lead to technology violations in further work.

Possible adverse effects:

- the appearance of cracks;

- manifestations of spots on the facade;

- local detachment of the finishing layer;

- swelling of the finish.

To avoid such defects, you should not blame the builders and save on building materials for decoration. If you want to do it cheaper and faster, in the end nothing good will come of it. We'll have to redo everything, buying new materials.

When choosing a material, it must be taken into account that the mixture must have good vapor permeability, high frost resistance and be compressive strength.

Materials for plastering the facade of the house

In order for the blocks to be protected from the penetration of rainwater for a long time, and the primer to hold firmly, a hydrophobic and strengthening composition based on acrylate siloxane is needed. The material must be selected so that it can be applied on a loose surface. Before starting the primer, the facade must be dry and the temperature must be 10-25 degrees. Before starting work, all defects and cracks are supposed to be repaired.

Reinforcement is then made using alkali-resistant fiberglass mesh. Its use is necessary for the integrity of the finish. The grid is attached to the wall of the house in two ways:

Reinforcement is then made using alkali-resistant fiberglass mesh. Its use is necessary for the integrity of the finish. The grid is attached to the wall of the house in two ways:

- the mesh is attached to the wall of the house using special screws, but this is not the most reliable way;

- the mesh is pressed into thin-layer plaster for reinforcement, which is also a primer layer.

When choosing a material, you should not save. According to the technology, cheap meshes may not be suitable.

After reinforcing the wall, you can proceed to the stage of applying plaster. To do this, you need to know how to prepare plaster for home decoration, and what types of it are.

Facade plaster for aerated concrete

Silicone - has a long service life, is resistant to ultraviolet rays and temperatures, has water-repellent properties. The basis of this coating is silicone resin. Plaster is not cheap, having a number of features, it is worth it.

Decorative - indispensable for home decoration. It contains colored pigments that do not require further painting. Such plaster saves energy costs and is the key to an attractive appearance of the facade.

Acrylic - resistant to temperature and moisture, hides minor defects. The plaster is plastic and cheap, but quickly absorbs dust, reducing the facing color brightness.

Mineral - applied by machine. The dense structure provides a durable coating, protects the surface from temperatures.

Facade - has leveling and protective properties. Inexpensive and high-quality protection for the facade of the house. Functional plaster is easy to apply to the surface.

Cement-sand - the most famous solution, but not suitable for aerated concrete blocks.

Applying mortar to the wall

When a suitable plaster is selected, you can begin to prepare and apply the mortar outside the house. In a container, dilute the dry mixture with water to the desired consistency. Basically, proportions are written on the packages. Next, the mixture is stirred with a construction mixer. When the solution is ready, you can proceed to the finish.

Plastering can be done in several ways:

- with a trowel, throwing the mixture onto the wall, smoothing it with the bottom surface;

- with a wide spatula, tightly pressing against the wall, moving it from bottom to top;

- with a small spatula, throwing the mixture onto the wall along the outer plane. After that, everything is aligned with the rule.

Finishing technology is not difficult. The main thing is to maintain a round-the-clock temperature regime. In hot weather, the plaster will crack, and in frost, the mixture will not cling to the surface.

If you are new to plastering walls outside, there are a number of rules you need to know that will help save time and money on redoing work:

- the solution must be applied in even layers, otherwise cracks form when the uneven layers dry;

- so that the wall outside is free of stains, take a break for no more than two hours;

- impurities that get into the solution will accelerate the peeling, therefore, it is impossible for water, dust or dirt to get into the mixture or onto the wall;

- if lumps are present in the plaster, it should not be applied to the surface.

If you have doubts about the choice of selection for the facade, you need to contact the experts. It is also worth noting that when buying materials, you must buy goods in places where there is relevant documentation.

Aerated concrete has long been loved by private developers for its excellent performance and very attractive cost. However, before starting construction from it, you need to study all the "pitfalls" in this matter in order to build a high-quality and durable structure. So, when planning the finishing, it is important to know how to plaster aerated concrete inside the house, and what materials are prohibited. What are the reasons for such restrictions and what kind of finish is ideal for gas silicate blocks, we will consider below.

Features of finishing aerated concrete walls

Before you plunge headlong into the issue of finishing the walls, you must first understand the structure of gas blocks, from which the quality of the future home will completely depend.

The main way to obtain this cellular material is the introduction of special additives into the composition of the concrete solution, which, when reacting, form air bubbles that tend to break out. They simply streak the aerated concrete body not only with voids, but also with thin channels, forming a surface that resembles natural pumice in its texture. Such a structure has excellent positive properties with the correct final processing of blocks:

- high sound absorption coefficient;

- good level of thermal insulation;

- "breathing" walls create a unique microclimate in the room, keeping warm in the winter season and cool even in the most intense heat;

- the porous structure of aerated concrete is not subject to the emergence and maintenance of colonies of fungal and other microorganisms, which, as a result of their vital activity, destroy walls.

The porous structure of aerated concrete

But despite these wonderful performance characteristics, aerated concrete also has disadvantages due to its structure:

- the porous structure is subject to increased water absorption, which is fraught with the rapid destruction of blocks;

- products with the highest density index, and, accordingly, strength, do not differ in resistance to mechanical stress, leading to spalls and cracks;

- the heterogeneous structure, which retains heat so well, is very sensitive to wind. Unprotected bare aerated concrete walls are strongly blown, and it is cold inside them, even despite a well-organized heating system.

Taking into account all these negative circumstances, we can conclude that aerated concrete walls need to be finished. But it must be done as competently as possible so as not to disturb the microcirculation inside the walls, which can lead to destructive processes.

Vapor permeability

The porous structure, which has been talked about so much, has another property - good vapor permeability, which is the key to the durability of any structure made of cellular concrete.

In the process of life, people release a large amount of all kinds of moisture into the atmosphere. Just imagine how the air is saturated with it when ironing, washing, drying clothes, cooking or taking a bath. Of course, part of the vapors formed is removed using artificial and natural ventilation, but the main volume falls on the walls. In its pure form without finishing, aerated concrete perfectly passes moisture without retaining it inside its body.

Another thing is if there is a facade and interior cladding, and it is required for such wall material. Therefore, both finishes should complement each other, organizing the maximum natural removal of moisture.

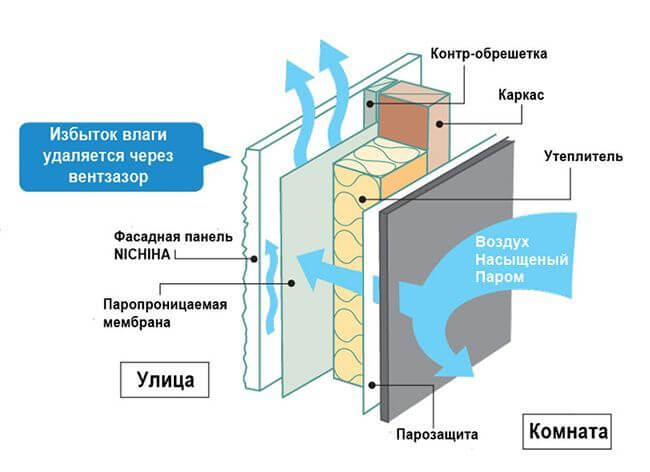

For example, a ventilated facade system was chosen as an external finish. In this case, the provided ventilation gap does not disturb the natural balance of moisture in the aerated concrete wall, leaving complete freedom for the vapors to escape. Under such circumstances, any plaster for aerated concrete can be used.

Ventilated facade - the best type of exterior finish for aerated concrete walls

In the case of a wall insulation device, you need to pay attention to the characteristics of the base material. For example, mineral wool fully complies with the requirements - it insulates with high quality and does not prevent the removal of moisture. As in the previous example, the circulation of steam is not disturbed and the wall remains dry, so any plaster mixture can be chosen.

How to maintain natural moisture balance

But often, for one reason or another, facade decoration is arranged to bypass the basic rules, or, even worse, the insulation was made with foam sheets (its vapor transmission capacity is almost zero) without a ventilation gap. This leads to the accumulation of moisture in the thickness of the wall, which eventually manifests itself in damp corners, the collection of condensate in the room - and these are the first harbingers of the appearance of fungal mold.

The consequence of violation of the vapor permeability of aerated concrete walls

Such a serious defect can be corrected only by using materials for interior decoration, whose ability to pass vapors is much lower than that of aerated concrete. This shielding method will prevent the accumulation of moisture inside the walls. Best to use:

- hydrophobic impregnations;

- paints with a special composition;

- waterproof wallpaper;

- cement-sand plaster mortars of dense consistency.

But in this case, the importance of a high-quality ventilation device is significantly increased so that the accumulated moisture does not settle on the walls and inside the room, forming a greenhouse effect.

In order not to complicate the construction process, it would be most correct to initially produce interior decoration. After all, the repair involves a large amount of evaporated moisture, which simply needs to go outside, and it is best if it does this through the “bare” gas silicate walls.

And one more small nuance regarding the timing of the processing of walls made of aerated concrete blocks. Any cellular materials shrink well, which, in turn, negatively affects any fine lining - this usually manifests itself in cracking and peeling of the decorative layer.

Therefore, it is recommended to carry out both internal and facade finishing processes at least six months after the complete erection of the building box and the roof device. It is best to plan this stage of construction in the spring - summer period. As mentioned above, the interior decoration is carried out first, after the end of all processes, in a month you can start processing the facade.

What plaster to prefer for interior decoration

As noted above, aerated concrete blocks are characterized by a high degree of water absorption, which can lead to excessive drying of the applied layer of plaster. This is especially evident on gypsum compositions and cement-based mortars - fast drying, cracking and shedding. If, on the other hand, we go from the opposite, and unnecessarily saturate the wall with water, then it will simply be impossible to plaster it, since the applied layer will not be held on the aerated concrete base.

Choosing the right materials will help solve this problem:

- primers of deep penetration with a special composition. When applying them, the main thing is not to overdo it and not oversaturate the surface of the wall with moisture. Therefore, before use, read the instructions and follow them strictly;

- special mixtures intended for plastering exactly gas silicate blocks. Their composition perfectly protects such “capricious” porous surfaces. But this is subject to the dilution of the plaster in the correct proportions with water. Only following the instructions for use from the manufacturer will help not to make a mistake in this matter.

But that's not all. The cellular surface does not have good adhesive qualities. For this reason, it is initially necessary to apply a rough layer of plaster with a thickness of at least 5 mm. But even this finish is prone to cracking and flaking. To prevent this, a plaster mesh is used. Fiberglass or polyurethane sheets are best preferred due to their excellent alkali resistance and long service life. Only after applying such a reinforced plaster layer and its complete drying, you can safely proceed to the fine finish.

The best plaster mixes

Having figured out a little about what parameters the finishing mixture should meet, let's look at its most popular and effective types:

- plaster compositions based on silicates, namely "liquid glass". They are perfectly combined with aerated concrete surfaces, especially in terms of vapor permeability. But there is a small "but". Such plaster mixtures are incompatible with many types of fine finishes, for example, based on acrylic, latex, silicone;

- gypsum plasters with perlite sand. They are ideal for aerated concrete wall surfaces, as indicated on the package. Any material for finishing is suitable for them;

- plaster mixtures on a cement-lime basis with the addition of optimizing additives. Such compositions were invented specifically for finishing cellular material, even without a preliminary primer. The internal plaster of walls made of aerated concrete of a similar plan has not only excellent adhesive properties, but is also applicable for both rough and finish finishes.

The use of such plaster compositions is ideal for gas silicate walls and, if desired, you can use them to apply a leveling layer yourself. Like all specialized materials improved for one application, these mixtures have a very high cost, which in the end adds up to a decent amount.

But there is an alternative that will economically resolve the issue of internal plastering - the use of a conventional cement-sand mortar in a ratio of 1:5. But it must be used with extreme caution in relation to aerated concrete surfaces and not overdo it with the addition of water to the working mixture.

The process of self-interior plastering

Even if you decide that indoor plastering of aerated concrete walls will be done by craftsmen, it will not hurt to know the process of its implementation. After all, even professionals can sometimes make mistakes, and control from the outside will help to avoid annoying shortcomings.

Preparing for plastering

The algorithm of the process for preparing walls for plastering is quite simple in execution, in which it is impossible to make a mistake. Therefore, you can do it yourself. This will require:

- or plastic 100-120 cm wide;

- adhesive for ceramic tiles;

- deep penetration soil;

- notched trowel with 5-6 mm teeth.

Stage 1. Carefully inspect the walls for construction "jambs". For example, cracks and chips are subject to putty with alignment to the general level of the walls. For these purposes, a regular repair mortar is suitable, however, if it is not needed so much, then it is best to use an adhesive specifically designed for aerated concrete.

Stage 2. After drying the restored parts, go over all the walls with a stiff brush to remove dirt and dust.

Step 3. Apply primer in one coat. You can do this in a way convenient for you, for example, using a roller or brush. To reduce the consumption of the primer solution, experienced builders will use conventional sprayers. If there are none at hand, then you can just as well use an old model of a vacuum cleaner, the principle of which is to blow air. Only after high-quality drying of the first layer, you can start applying the second.

Stage 4. When the primer is completely dry, you can safely dilute the glue, according to the instructions and cut the plaster mesh into strips, the length of which should be equal to the height of the walls.

Stage 5. Starting from the bottom, pour the prepared glue onto the wall, gradually moving up. The thickness should be approximately equal to a layer of 5 mm, and the width should be slightly larger than the width of the mesh.

Step 6 Apply a strip of stucco and press it firmly into place on the wall. Now you can level the adhesive layer with a notched trowel so that the direction of the grooves runs horizontally. This improves adhesion to both the wall and future plaster.

Applying plaster

After the reinforced layer is completely dry, you can safely proceed to the main plastering process.

Stage 1. Wielding the building level, profiles are exposed - beacons.

Stage 2. The working solution is mixed according to the instructions. If the choice fell on the traditional cement-sand composition, then it is taken in a ratio of 1: 5, a plasticizer is added and kneaded to a thick consistency.

Alignment of the solution on the beacons

Stage 3. A solution is thrown between the two beacons along the entire height of the wall. Using the rule, the resulting layer is leveled to the required level of smoothness. Once again, attach the rule to the wall and check if there are gaps between them. If there is, add a mortar and level it, no - fine, plaster all the walls in a similar way.

The described plastering technology is quite simple and even an inexperienced master can successfully use it. The main thing is that it is correctly chosen how to plaster the walls of aerated concrete inside the house.

Aerated concrete blocks are one of the most popular types of structural building materials. The plaster walls of aerated concrete indoors will be analyzed in detail and described in this topic.. You will learn in what sequence and why it is worth finishing the house from aerated concrete and get acquainted with additional materials, the use of which is aimed at obtaining the highest quality and durable surfaces when plastering walls.

Sequence

When performing finishing work on buildings erected from aerated concrete segments, it must be understood that the properties of aerated concrete walls are very different from walls that are built from bricks, polystyrene slabs or other materials. These blocks have a number of positive qualities, which are due to their porous structure. The most important is the ability to pass oxygen into the room and remove water vapor and carbon dioxide, which are formed in the process of human life, to the outside. The desire to preserve them is the main criterion when choosing how to plaster aerated concrete.

But it is also necessary to understand that the throughput of the material requires strict adherence to the sequence of finishing the interior rooms and the facade of the house from aerated concrete. The most gross mistake of builders who have little experience in finishing buildings from this material is to first plaster the facade of the house, and then move on to its interior decoration.

Especially negative consequences under this scheme will be manifested if the builders completed all the outdoor work in the summer, leaving the interior decoration for the winter. Water, being an integral part of the preparation of mortars for wall plastering, will mostly evaporate and be removed to the outside through ventilation holes and pores. When the outdoor temperature drops below 0 ° C, water vapor will accumulate in the form of condensate inside and at the interface between plaster and aerated concrete.

When the accumulated condensate freezes, the integrity will begin to break, as well as the peeling of the outer plaster of the walls from the base and its cracking.

Thus, when starting the finishing of a building from aerated concrete blocks, it is imperative to make sure that the interior finishing of the building is carried out first.

Only then, after waiting for the complete drying of the plastered surfaces and the normalization of the humidity of the walls, you can proceed to work on plastering the facade of the house.

If you are wondering how to plaster aerated concrete walls, then this will not be a completely correct question. The plastering technique itself differs little from similar works on other materials. If you have at least some experience in their implementation, then you can do the plastering on aerated concrete with your own hands. Starting finishing, it will be right to ask yourself what to plaster.

Saving unique properties

Depending on the goals set for the builders, the plaster for aerated concrete inside the building can have completely opposite characteristics. The first option is wall plastering with materials designed to preserve the unique features of aerated concrete and improve the vapor permeability of walls. It is the most common when interior decoration is performed.

Wall plastering with this finishing option excludes a cement-sand mortar, which significantly reduces the vapor conductivity of the walls. To achieve this goal, special plaster mixtures based on gypsum are used, designed for plastering on cellular concrete. When using them, the primer of the surfaces to be plastered is not mandatory, but the use of reinforcing materials is recommended. On the outside of buildings, a metal mesh is usually used. For reinforcing the inner layer of plaster, fiberglass mesh will be a more suitable material.

Vapor barrier finish

The second type is the introduction of such materials in which the wall plaster will have maximum vapor barrier. At the same time, there is no question of preserving the unique characteristics and the internal microclimate will become close to reinforced concrete buildings. In this case, the plaster of the facade of the house will be more durable. To obtain these features, a polyethylene film is most often used, which is laid under any finishing layer. In this case, sand-cement mixtures are used as plaster for aerated concrete. But it must be borne in mind that the addition of dolomite flour or lime to such solutions is excluded.

Plastering of walls with this finishing option should begin only after preliminary priming of the walls. To increase the vapor barrier properties, you can use oil paint on the walls. Also on the market of modern building materials, special vapor barrier plaster mixtures are widely represented, the use of which can reduce the vapor conductivity of the surface by more than 25 times. Although they have a higher price compared to polyethylene film, avoiding peeling and cracking along the line of contact between polyethylene and plaster can be economically justified when finishing walls made of aerated concrete. But in this case, the use of a reinforcing mesh will improve the strength characteristics.

In general, this is all that is worth knowing. Starting to plaster aerated concrete and relying on the information received, you can achieve maximum results with minimal effort. The debate about which is better, vapor permeability or vapor barrier, will continue forever. Supporters of each of the described methods will always find arguments in their favor.