Plaster is a fairly common design option for the external surfaces of buildings. But to create a truly unique exterior, it is not enough to simply apply a solution. Therefore, after it dries, facade paint on plaster is used for further finishing work.

An exterior paint for plastering should have the following characteristics in order to stay on the surface longer:

- Resistant to mechanical stress, such as abrasion.

- Biosecurity: Finished coatings must be free from fungi, mold and pathogens.

- The composition of the material must contain a special component that will protect the coating from exposure to sunlight.

- Facade paints for plaster must be resistant to the effects of various chemically active substances.

- Components are added to such paints to increase fire safety.

- The material is elastic, so that the coating does not crack when the building shrinks.

Facade paints must be very durable, resistant to external factors

Facade paints must be very durable, resistant to external factors On a note! Some formulations have an antistatic effect. They repel dust, which is very important for buildings that are located near large roads.

Types of facade paints

The modern construction market offers the buyer a huge amount of facade paints for exterior plastering work. They are made on the basis of various materials and with the addition of various components, on which their performance depends.

Based on liquid glass

This facade paint for plaster for outdoor use also has another name - silicate. It is made on the basis of silicate glue, to which mineral pigments and fillers are added. The service life of such coatings reaches 20 years. This indicator was achieved due to the high level of vapor permeability, therefore, no water accumulates under the coating. As a result, the plaster for painting will not absorb much moisture and will not fall off the wall. The main disadvantage of this material is its susceptibility to mechanical stress. In addition, the paint is not elastic, so it can crack very quickly after drying.

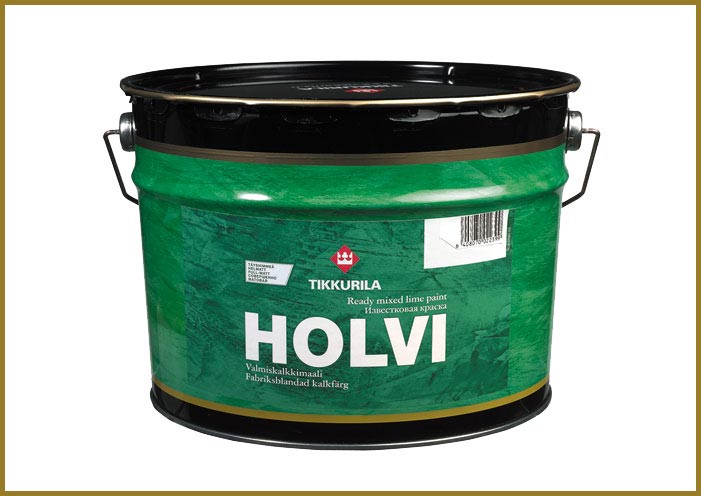

Lime based

Such paints for the facade on plaster are made on the basis of slaked lime. The main advantage of this material is its low cost, but it is important to understand that having saved on the purchase of the coloring composition, in the future you will have to spend annually on maintaining the facade in its normal form. The paint gets dirty and washed off with water, so after the spring rains you will have to re-paint the house. It should also be said that slaked lime is distinguished by its bactericidal properties, as well as a good level of vapor permeability. The range of colors is usually limited to light pastel tones. You can additionally purchase a color scheme and add bright colors, but such material will quickly fade in the sun.

Cement based

In some cases, cement-based paints are used to paint plaster. The basis of this composition is white Portland cement, but you can add color to get the desired color. Unlike lime-based materials, this paint is not washed off by rain, but pathogens can develop on it. The cost of cement materials is also low, but they have not gained popularity among domestic buyers.

Acrylic resin based

At the moment, this finishing material is considered the most common, since it has a good price-quality ratio. In addition, the paint has a good mechanical strength. But there is also a significant drawback - acrylic does not allow steam to pass through, as a result of which moisture will accumulate under the coating and can lead to its rapid deterioration. This material is divided into two types depending on the solvent used: water-based and organic-based. The latter are most often used for painting facades.

Silicone based

Such materials are considered the best for finishing plastered facades. They are slightly inferior to acrylic compounds in terms of elasticity, mechanical resistance and cost, therefore they are not widely used. After processing, the plaster layer does not absorb moisture, but at the same time has a high vapor permeability. Silicone paint is characterized by low consumption, resistance to high and low temperatures, as well as their drops. The finished coating is dust-repellent and not exposed to UV rays.

Silicone-based exterior colorant

Silicone-based exterior colorant Other types of paints

There are several other types of facade paints that are quite rare on the market. For example, perchlorovinyl paint. The main advantage of this material is its low cost. In addition, the composition is produced in a wide range of colors and can be applied to surfaces even at negative temperatures. The paint protects walls from weathering, corrosion, bacteria, fungi and mold. But at the same time, the service life of the coatings is only 4 years, and the presence of flammable components makes the material unsafe.

Structural compounds are sometimes used for external finishing work. In fact, such paints are more like decorative plaster mixes. The advantages are plasticity and elasticity, due to which it is convenient to work with the material. The disadvantage is a small number of colors, high cost, short service life of finished surfaces. In some cases, latex is added to such formulations to increase the level of surface protection.

Preparatory work before painting

The first step is to prepare the surface. To do this, you need to assess her condition. If the plaster is old, frayed, stained and looks unsatisfactory, then you will have to completely remove it and apply a new one. If the plaster layer looks normal, then you need to tap the entire surface with a hammer to find weak points. Fragments of plaster are removed, and the resulting holes are sealed with putty. At the end, the walls are washed and allowed to dry. Then apply a deep penetration primer in two layers and also leave to dry.

Stages of surface preparation for painting

Stages of surface preparation for painting Now you should calculate the required amount of paint. First, you need to calculate the area of each outer wall and add the resulting numbers. Then multiply the result by the average material consumption - first for the first layer, and then for the second. The fact is that most facade paints are applied in several layers, each of which requires a different amount of material. This is done to improve the quality of the finished coating. If you try to save money and apply only one layer, then after drying you will see a stain of a different color.

At the very end, you need to prepare everything you need, for the event you will need the following tools and materials:

- Stepladder or scaffolding.

- Roller or paint brush.

- Dye.

- Drill with mixer attachment.

- Measuring capacity.

- Container for paint.

- Protective clothing, goggles and gloves.

Instructions for applying paint to plaster

The first step is to install the scaffolding, after which the composition should be mixed. This can be done with a construction mixer, a drill with an appropriate attachment, or a simple wooden lath. Then you need to measure the exact amount of color and pour it into the paint, then stir it again.

You should know! Adding color is the most crucial step. It is important to be accurate when carrying out this process so that the color of different fragments of the surface does not differ.

Pour the paint into a special container, dip a roller or brush into it, then squeeze the tool and apply the composition to the surface with vertical movements, processing the coating from top to bottom.

After the first layer has dried, proceed to the second. Everything should be done in the same way, but the movements should be horizontal. As a result, the strokes will overlap, which will provide a denser, even coverage. It is recommended to work quickly, do not delay the staining for a long time. The best time for the procedure is a dry and warm period, for example, late spring.

Facade painting is one of the simplest types of finishing work that even an inexperienced home craftsman can handle. Thus, you can significantly save on the services of painters, as well as create an exterior with your own hands. To obtain a high-quality result, it is enough to follow the above instructions and manufacturer's recommendations.