Modern technologies make it possible to fairly reliably perform the exterior decoration of houses of any height and configuration using the ventilated facade method. The main advantage of using this method is that the walls of the house are transformed according to the most intricate options of the owners and are insulated with high-quality material.

General description and structure of ventilated facades

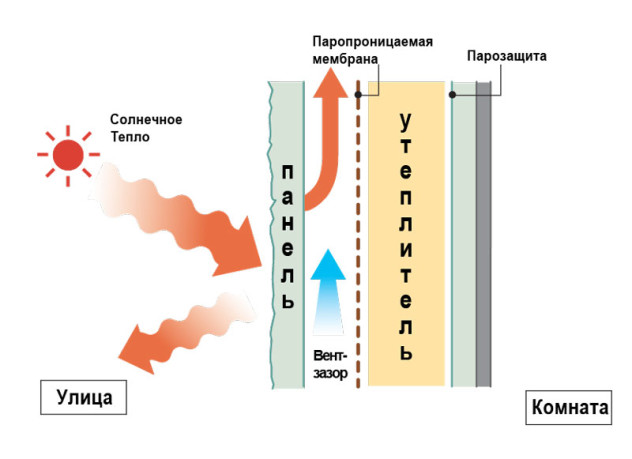

The structure of the structure resembles a puff cake. It consists of several "layers" that perform specific functions, and together they are called ventilated facades:

Metal subsystem or wooden crate

The frame (crate) consists of the following elements:

- fasteners (brackets, screws, rivets);

- Guides (profile or bars).

The guide metal profile, with the help of self-tapping screws and brackets, is fixed to the wall surface of a frame, timber or log house. Installation of lathing from a wooden bar is carried out without the use of brackets, but the term of such subsystems is shorter. The horizontal or vertical direction depends on the type of facing material selected.

Thermal insulation

Mineral wool or expanded polystyrene (polystyrene, carbon) is fixed to the surface of the walls of a residential building with the help of special "fungi". When choosing and calculating, it is recommended to take into account the thermal insulation data of a specific type of insulation. When performing work on your own, the choice depends on the preferences of the owner of a private frame structure, which may turn out to be erroneous.

useful in work

Before fixing thermal insulation, walls of frame, log, timber and any other wooden structure are recommended to be treated with an antiseptic.

Protective membrane

When insulating the facade structure with mineral wool, it is necessary to protect it from moisture and weathering. This is achieved by using a moisture-proof vapor-permeable membrane. It protects the heat-insulating material from weathering and moisture ingress, contributing to its gradual destruction and violation of the integrity of the system, which can affect the load-bearing walls of a residential building.

When choosing and purchasing thermal insulation for residential buildings, it is necessary to pay special attention to fire safety. The material must have the necessary certificates and belong to a non-combustible class. For example, class "C" expanded polystyrene maintains the combustion process for no more than 4 seconds, and class "F" - 1 second.

When using expanded polystyrene, membrane installation is not required (unlike mineral wool).

It's important to know

Despite the numerous advantages, the authors do not recommend the use of polystyrene or expanded polystyrene in ventilated facade systems, since in case of fire, under the influence of natural draft, such insulate it will burn for a while and can contribute to a fire on a wooden wall.

Air gap

The presence of a certain air gap between the insulation (or the wall of the house without insulation) and the facing material allows moisture to be removed to the outside. It is because of the presence of this space that such structures got their name.

The size of the gap is determined using complex mathematical calculations and is calculated during the design phase. As a rule, the minimum air gap should be at least 40 mm. Errors in these values can lead to moisture ingress on the thermal insulation (with a short distance), as well as hum in strong winds (with a large gap).

Decorative finishing

The cladding is fixed on the guides, the fastening takes place depending on the material used for specific residential buildings. Depending on what the owner of a private house preferred, fasteners are selected.

Types of facing materials

The cladding of private houses can be made using a wide range of finishing materials, each of which has its own distinctive qualities, characteristics, and is also made from different raw materials.

Natural wood

- euro lining;

- block house;

- planken.

A natural stone

- Granite;

- marble;

- travertine;

- agglomerate.

Ceramics

- Porcelain stoneware;

- terracotta;

- clinker.

![]()

Hardware

- Siding;

- front panels;

- composite panels and cassettes.

Other materials

- Facing brick;

- HPL - panels;

- fiber cement plates.

Facade compatibility

The exterior decoration of a residential wooden log house, made using the "ventilation facade" technology, compares favorably with other methods of facade insulation in that all the useful natural qualities of a wooden structure are preserved. Multilayer "breathable" structures have proved to be excellent in the operation of any building.

A wide range of fasteners allows installation on almost any wall of residential buildings made of various materials. The difference may lie only in the type of insulation. For example, the walls of a frame or log house are insulated with both expanded polystyrene and mineral wool, but the facade of a log house is only the latter. This is due to the external structure of the surface of the walls. Rigid foam sheets cannot be closely applied to the rounded shapes of a log building, and mineral wool has the properties of bending. Another good option for insulation is the use of eco-wool.

If the "wet facade" technology is used for finishing a stone house, then "breathing" structures can be erected on any type of wall.

Technology advantages

Ventilated systems have certain strong factors relative to other types of insulation and exterior finishes. The main advantage is versatility. "Breathable" structures can be used on any surface, regardless of the number of storeys, the configuration of the bearing walls of private buildings: log, squared or frame type.

Among the many advantages of this design are the following:

- A wide range of materials that can be used for decorative wall cladding;

- heat and sound insulation of a frame or timber structure;

- increased service life, durability is the most important factor for wooden buildings;

- there is no need to constantly maintain the facing material in good condition. Except when using wood facing materials (they must be treated with special chemical impregnations and solutions or varnishes).

- most of them have a certain resistance to mechanical damage, and some are considered anti-vandal material at all;

- fire safety;

- no extra work is required to replace one cladding element. It is enough to dismantle it and then install a new one.

It's important to know

All of the above characteristics are inherent in frame buildings or any other type with strict adherence to the technical requirements for installation, as well as the material used.

Thanks to the qualities that have proven themselves on the good side, such a decorative solution is actively used throughout Russia. Gradually, the number of buildings, the outer cladding of which is made in this "breathing" way, is becoming more and more, which allows us to speak about their popularity.