the decoration of a private house is as important as the interior, because it is its "face", reflecting the tastes of the owners and making the first impression of them. In addition to performing a decorative function, facade finishing has a practical value - it insulates, protects the supporting structure from weathering, temperature changes. Modern types of finishing the facades of private houses, photos of which can be found in this article, are diverse, have their own advantages and disadvantages.

Types of materials for finishing the facades of private houses

The choice of a certain type of finishing materials for the facade depends on several factors:

- stylistic orientation of the building facade design;

- climatic features of the area;

- the financial capabilities of the homeowner.

For facing the external walls of a building, the following are most often used: artificial and natural stone, plaster, brick, metal or vinyl siding, porcelain stoneware, plastic panels.

Facade panels

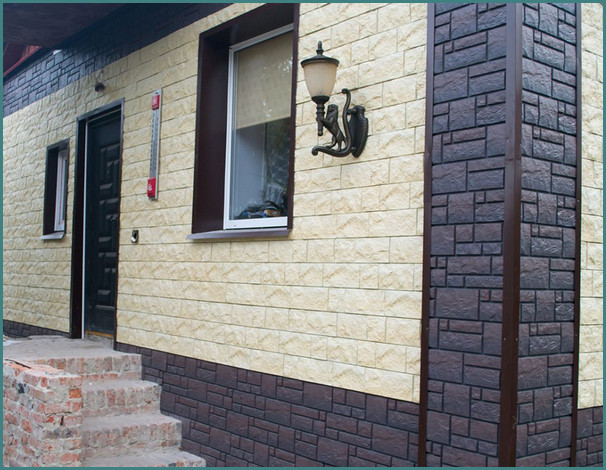

Facade panels are a fairly popular type of material. This is a ventilated facade in the form of panels measuring 0.5-1 sq m. There are several types of facade panels:

- PVC panels - produced with imitation of brick or stone. The advantages are affordable price, variety of colors, light weight, durability, easy installation. PVC panels are mounted on a profile or bar lathing;

- fiber cement - have a fairly high price, but it is justified by the advantages of the panels, including resistance to low temperatures, which makes it possible to use this material in areas with harsh conditions, as well as light weight, durability, and a variety of textures. Panels are mounted on a metal frame;

- made of polystyrene - they have a reinforced layer of plaster, do not require the installation of the frame. The disadvantage of foam panels is that they cannot be attached to the walls of wooden houses, as this can cause condensation and wood rotting;

- metal - made of polymer coated metal of various colors, durable, fireproof. But they are suitable mainly for finishing the facades of non-residential buildings, since they poorly retain heat in winter and heat up in summer;

- wooden - made of pressed wood treated with a special impregnation. They retain heat well, are easy to install, but such panels belong to the class of highly flammable materials;

- glass - panels made of impact-resistant glass with good sound and heat insulation, but expensive as a material and in installation.

Glass

Glass  Styrofoam

Styrofoam  Metallic

Metallic  Wooden

Wooden Sandwich panels

This is a finish made of two metal sheets connected together, between which there is a heater with a thickness of up to 70 mm and a vapor barrier layer, which gives the material good thermal insulation properties. Due to their light weight, their installation is not particularly difficult. In addition, the sandwich panel facade is durable, moisture resistant, fire resistant. If the outer part of the panel is deformed, it can be easily restored without replacing a large area of the facade.

With all the visible advantages, sandwich panel finishing cannot be called cheap. Installation of this finish can be done both on the frame and directly on the walls of the house. In case of poor-quality installation in cold weather, the space between the joints can freeze through, which leads to a violation of the thermal insulation properties. When finishing the facade without violating the installation technology, such problems do not arise. Due to their properties combined with aesthetic appearance, sandwich panels are widely used as a finishing material.

Decorative plaster

Plastering is not only decorative, but also a protective coating of the walls of the house from the destructive effects of external factors, as well as helping to retain heat, a material. Plaster is the most "breathable" of all finishing materials, it is resistant to moisture, does not crack from frost with the correct application technology and high quality material. Modern decorative plaster can be used for painting. Among the disadvantages is the fact that plastering is a rather costly and energy-intensive process.

Plastering is done on a prepared base or using a reinforcing mesh, which will protect the plastered facade from cracking.

There are several types of decorative plaster:

- mineral;

- acrylic;

- silicate;

- silicone.

Mineral plaster is varied in its shades and affordable. It resists the reproduction of microbes, is moisture resistant and is not afraid of direct sunlight. The composition of the mineral plaster is suitable for applying to surfaces of any materials. The disadvantage of this type is low elasticity, due to which, when the house shrinks, the plaster can crack.

The second type is more elastic than the first. When using acrylic plaster, cracks do not appear when the building shrinks, the original appearance of the finish remains for several years. But this material is combustible, prone to rapid contamination and its price is higher than that of the mineral one.

Silicate and silicone plasters are the most durable finishing materials, resistant to dirt and external influences. Their common disadvantage is their high cost, with the difference that silicone plaster requires less application effort than silicate plaster.

Facing brick

Finishing the facade with facing bricks will be the best solution for those who want to give the appearance of the house solidity and rigor, but cannot use real bricks for this. This option is inexpensive, practical and fast, besides, facing bricks are presented on the market in a rich assortment, thanks to which the appearance of the building can be transformed in accordance with the preferences of the owner.

It is an environmentally friendly material with good thermal insulation properties, which looks much more aesthetically pleasing than ordinary brick. The peculiarities of facing brick finishing imply a limitation of masonry in height up to five meters, otherwise you can forget about the strength of the facade finishing.

Brick finishing is carried out on a prepared surface treated with a waterproofing material using flexible fasteners of a certain amount per square meter. It is not recommended to use brickwork of wooden structures in order to improve the thermal insulation of the walls, since it is difficult to achieve a snug fit of the material to the wood.

A natural stone

The use of natural stone for decoration will allow you to create a presentable and solid facade of any residential building. This expensive material requires professionalism in working with it; it will be difficult for a beginner to independently make a finish from natural stone. Installation difficulties lie in the heavy weight of the material, due to which it does not adhere well to the surface. Therefore, during installation, the stone is recessed into the solution, fixing itself in it.

It is an environmentally friendly material, very durable and reliable, with excellent sound and heat insulation properties. If your financial situation does not allow you to decorate the facade of the whole house with natural stone, you can decorate its individual parts - the basement, corners, openings, combined with decorative plastering. The stone facade will become a reliable protection of the house from adverse external conditions for many years. The natural stone facade fits organically into any landscape of the area.

Fake diamond

With the help of an artificial facade stone, you can finish as solid and sophisticated as from natural, but less financially. Artificial stone with imitation of natural texture, made of gypsum or cement. Gypsum stone weighs less, so it is suitable for wall cladding with insulation, while cement-based stone is ideal for cladding hard surfaces. Unlike natural stone, the installation of an artificial one is easier, a layman can easily handle it.

When buying a decorative facade stone, you should pay attention to its purpose - for interior decoration or for exterior, since they differ in their strength. In addition to its weight, this finishing material differs from natural stone in its plasticity. For the rest of the parameters - durability, resistance to external influences, a variety of textures and shades, artificial stone is not inferior to natural.

Porcelain stoneware ventilated facades

Porcelain stoneware is called artificial granite, which is characterized by such quality characteristics as durability, resistance to chemical and physical influences, a variety of textures and stable shades, increased moisture resistance and frost resistance, incombustibility of the material. A feature of the installation of this finishing material is that it cannot be laid directly on the mortar. A ventilated facade is produced from porcelain stoneware, that is, a curtain facade system that ensures air circulation along the wall, providing heat and sound insulation, as well as resistance to mold or mildew on the walls.

With the help of porcelain stoneware, you can create an original facade of your house, since there are many types of it with different types of surface: matte, satin, glazed, polished, mosaic, and structured with imitation of various textures. Ideally, you need to purchase porcelain stoneware with a tile thickness of at least 12-16 mm.

Siding

The most popular and affordable material is siding. Installation takes place both on insulated walls and without insulation. Siding is often used to hide defects in the exterior walls of a building. It has good waterproofing properties and a wide range of textures and shades.

There are the following types of siding:

- vinyl;

- metal;

- wood;

- basement;

- cement.

Vinyl

Vinyl  Wood

Wood  Metal

Metal  Fiber cement

Fiber cement  Basement

Basement The first type is made of PVC, its surface can imitate various textures. The material is lightweight, resistant to mechanical stress, and inexpensive. But the fasteners used to install vinyl siding are quite expensive in terms of cost. During installation, it is recommended to use the help of specialists, since if incorrectly fastened with a fixed fixation, the panels may deform.

Metal siding is made from aluminum or steel. The disadvantage of this type is the susceptibility to corrosion in the event of surface damage. Wood siding is aesthetic, safe, but impractical and requires special care.

Insulation "wet facade"

Insulation technology "wet facade" consists in the use of solutions and building compounds diluted with water at all stages of work. After the completion of the insulation, the facade of the building looks like when finishing with decorative plaster. As a result, when using this technology, two goals are achieved - insulation and decorative finishing.

The following materials are used as materials for this system:

- insulation - polystyrene foam, mineral wool, foam can be used. The first is not used so often due to the fact that polystyrene foam has poor adhesion and vapor barrier. Mineral wool is nonflammable, has high vapor permeability, but has a greater weight and cost than foam. The thickness of the insulation is calculated depending on the climatic zone and the material of the walls of the building;

- reinforcing mesh;

- glue for insulation and mesh;

- plastic fasteners for insulation.

The “wet facade” insulation technology has a number of advantages: it is simple, it allows not only creating an insulating layer, but also a soundproof one. The system is light enough and can be mounted on any facade. In addition, the almost monolithic insulation does not allow the cold to penetrate into the gaps. The possibility of mold or mildew on the walls is excluded, and the outer layer protects against mechanical and weather influences. The service life of such a facade is at least 20 years. Among the shortcomings, it is possible to note special requirements for the quality of materials and work technology, as well as the fact that installation can be carried out only at a certain time - during the warm season.

The types of materials for facade finishing can be very different. In order not to be mistaken with the choice, you should carefully study the assortment, as well as familiarize yourself with the advantages and disadvantages of each of the materials.

Wet facade technology

Video

We invite you to get acquainted with the advanced technologies for finishing private houses.

Photo options for finishing the facades of private houses

The selection of photos contains options for finishing the facades of private houses of various sizes.