Maintaining the foundation of the house in excellent condition has the most positive effect on the condition of the building structures. The effectiveness of insulation, high-quality thermal insulation, and the correct operation of all communications depend on this. One of the most durable external coatings is considered a natural stone and decorative plaster, with the help of which you can qualitatively plaster the facade, giving it an attractive look.

Lime-based wall coverings have been used for thousands of years. From the tombs of the pyramids of Giza to the Sistine Chapel, lime stucco was one of the key elements of great architecture on six continents. The earliest plasters known to us were lime.

Plaster often contained significant amounts of dirt or clay, marble or brick dust, or even sawdust. The array of other additives ranged from animal blood or urine, cow dung, animal hair, eggs, keratin or glue, varnish, wheat paste, sugar, salt, sodium silicate, alum, lard, linseed oil, beeswax and wine, or rye whiskey. Additives or impurities are usually added to improve or modify characteristics such as cure time, plasticity, color, or volatility.

Practical material has a lot of varieties, advantages, in addition, all work on plastering walls is considered quite simple. This process belongs to the middle price category, but at the same time it has excellent fire resistance and waterproof properties.

Plastering is necessary to create an attractive appearance architectural object and at the same time protect the ventilated facade of the building from aggressive environmental influences.

In ancient India and China, rendering in clay and gypsum plasters was used to produce a smooth surface over rough stones or brick walls. In early Egyptian tombs, the walls were covered with lime and gypsum plaster, and the finished surface was often painted or decorated. Wicker plaster was used throughout the Roman Empire. The Romans used mixtures of lime and sand to create preparatory layers on which more subtle applications of gypsum, lime, sand and marble dust were applied.

Pozzolanic materials were sometimes added to get faster dialing. During the Renaissance, the addition of marble dust to plaster made it possible to produce fine details and hard, smooth finishes in hand sculpting and molding. After the Roman period until the 18th century, there was no use of hydraulic fluid. Hair has been used as a reinforcement, with additives to facilitate setting or plasticity, including malt, urine, beer, milk, and eggs. It is a form of carved, molded or modeled ornament made in lime putty or mixtures of lime and gypsum plaster.

Decorative plaster for the facade of the house has many advantages:

- resistance to sudden temperature changes;

- moisture resistance;

- strength and reliability;

- vapor permeability;

- improves noise and thermal insulation of the building;

- allows you to create a unique design;

- ease of application of the solution;

- low cost.

The cost of the finishing material largely depends on the quality of the ingredients that are included in the mixture.

During the same period, terracotta was reintroduced to Europe and was widely used for making ornamentation. Mona Lisa hangs on lime plaster in the Louvre Museum. Sand or marble dust and lime were sometimes added. In the same century, Italian artists, combining them with exemplary stucco decoration, introduced the sgraffito technique to Germany, also known as graffito or scratching. This technique was practiced in antiquity and was a quick and durable way to decorate building facades.

Here, layers of contrasting lime plaster were applied and the design scratched the top layer to bring out the color underneath. Plaster marble was an imitation marble made from limestone, pigments, water and glue. In the past decade, the American coined term "Venetian Plaster" has been attributed to a wide variety of products - many of which have nothing to do with each other. There are synthetic products, some natural. It has become a common and overused term.

Insulation plaster facades have certain disadvantages. If the technology is not followed, some problems may arise:

- vertical or horizontal cracks;

- spotting of the material;

- swelling of the surface;

- peeling of the finish layer.

If a cheap material was used, then after a few years it will be necessary to repair the facade plaster.

We prefer to be alone without a label and just say that we truly strive to bring you the finest natural and beautiful plasters and plasters to your doorstep, whatever you name it. Giorgio Vasari was a Renaissance painter, architect and historian. He biographies the lives of all major Renaissance artists and their techniques. He even coined the term "Renaissance". We like him so much that we named our company after him.

Used by the ancients and through much of the medieval Renaissance period, plaster is a wonderful material receptive to varied and effective artistic techniques. It was made by the Greeks of such exquisite quality that it was equivalent to marble.

Sequence of works for plastering the facade

Facade decorative plaster is a relatively uncomplicated type of construction work. If you have certain knowledge and skills, it is quite possible to plaster the facade with your own hands. For the successful implementation of the upcoming activities, you must strictly adhere to the established scheme.

Institute for Research on Freemasonry and Construction. The terms "plaster", "plaster", "plaster" and "render" are often used interchangeably, but have regional differences. In this article, "plaster" is understood as a composition that can be applied to all or part of a building and can be used in the same way for simple coating or for molded articles and decorations. Compositions range from lime and aggregate mixes to gypsum mixes, cement and sand works. Internal plaster was usually made of gypsum, marble dust and glue.

Surface preparation

Before plastering the facade, it is freed from various contaminants. Notches are stuffed onto the cleaned surface, this will ensure in the future a strong adhesion of the mortar to the wall plane. If plastering is carried out on a brick or stone wall, then the seams need to be deepened a little.

It was often formulated into ornamental shapes and polished to a marble finish. Drawn figures and ornaments were made using plaster. Carbon dioxide is derived from anhydrous calcium oxide or quicklime, sometimes described as unprotected lime or, misleadingly, as lumpy lime. Lime soaked in water is changed to calcium hydroxide or hydrated lime. When dried and ground to a fine powder, it is called hydrated lime or hydrate lime.

The addition of highly reactive forms of silica and alumina such as volcanic earth, ash or stone, brick dust or ground iron slag creates a hydraulic kit. Here lime is not determined by carbonation and can quickly harden even under water. The materials that cause this effect are called pozzolanic additives. Hydraulic lime can also be obtained by calcining limestones such as vines, which have a high silica content.

Facade surface cleaning

Facade surface cleaning

It is much more difficult to prepare wooden facades for the upcoming work. Small chips are made on the boards that make up the wall. These actions are carried out so that the wood material does not subsequently warp. After that, shingles are stuffed, which can be made from scraps of plywood or small planks. As a result, the entire structure should resemble a diagonal grid. Instead of shingles, you can use the facade decoration on the netting mesh.

Gypsum plaster has been used for rendering and mortars since the days of the ancient Egyptians. It is also used for molds, sculptures and castings. The plaster is prepared by heating gypsum minerals to about 150 ° C for partial removal chemically bound water, resulting in calcium sulfate hemihydrate, the main component of the gypsum of Paris. When it mixes with water, it turns into hydrated calcium sulfate, which quickly turns into an impenetrable solid, releasing heat and expanding slightly.

Its quick installation requires a lot of skill when working as a wall plaster. The set and workability of the gypsum plaster is controlled by various additives. Because it is slightly soluble in water, its use in temperate climates has been largely limited to interior decoration like wall and ceiling decoration, although it was sometimes used on its own or mixed with lime for exterior work such as placement or how to fill timber framed buildings. ... In such situations, the surface had to be finished to a smooth surface and protected by an effective roof.

Punching notches on the wall surface

Punching notches on the wall surface Tools and materials

To create a ventilated facade, it is necessary to use a mixture of binder, aggregate and a certain amount of liquid. Great distribution received dry mixes of industrial production. To prepare a ready-made solution, it is enough to add the right amount liquids. The disadvantage of industrial mixtures is the high consumption of plaster, which will affect the final cost of the work.

He was often protected with linseed oil paint. Today, gypsum has largely replaced lime for interior plasters. This is preferred because it hardens faster and shrinks less than lime. Lime is usually only used as a topcoat in modern plaster. These included the modification of gypsum plaster by heating and chemical treatment to obtain material that set reliably slower than gypsum but faster than lime. This eliminated the problems of difficulty in work and delays before decorating.

Cement-lime mortar is prepared from 1 hour of cement, 2 hours of lime mortar and 7 hours of sand. Cement plaster consists of 1 hour of cement and 3 hours of sand. The resulting composition is mixed until a homogeneous mass is obtained. Lime-clay mortar is prepared from 1 hour of clay, 4 hours of sand and 0.4 parts of lime. Gypsum plaster consists of 1 hour of gypsum, and 4 hours of lime-clay mass.

This was done by crushing and calcining "hard limestone", mixing lime with clay, and grinding the product in a fine suspension with water. It was fired, smashed to pieces, and fired a second time. Although this material was hydraulic, it was not as strong as modern cements because it was made with more low temperatures... It then reacted with the clay to form clinker, which was crushed and mixed with gypsum to slow down the installation. It was mixed with water for use.

The set occurs through the formation of calcium silicates and calcium aluminates in the film. They react with water from the star-shaped particles, which are blocked in order to ensure the strength of the cement. Modern ordinary Portland cement is a hard, gray, impermeable material mixed with sand for use as mortar and cut. The clay used was generally fine-grained to accommodate the parts; sand or ground clay called grog was added to reduce shrinkage and deformation during firing.

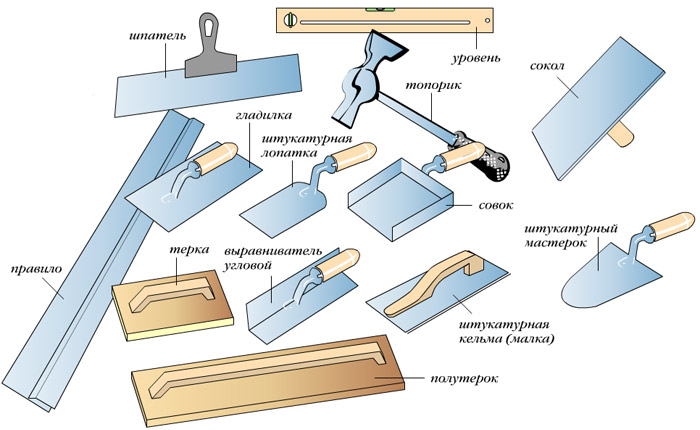

Various elements are used for plastering:

- tools (plastering trowel, falcon, float);

- beacons;

- reinforcing mesh;

- dry mixes, primer;

- corners.

Instruments

Instruments

Without certain skills, it is quite difficult to achieve an even surface of the walls the first time, it is best to plaster the facade of the house along the lighthouses. These are small rails, thanks to which the mortar is smoothed vertically with a special rule. Not so long ago, guides were made from wooden blocks of the same section, from plaster or from mortar. Today, metal beacons can be purchased at any hardware store. But modern material has certain drawbacks, therefore, time-tested technology is more suitable for many craftsmen.

An array of other additives ranged from animal blood or urine, eggs, keratin or glue, varnish, wheat paste, sugar, salt, sodium silicate, alum, lard, flaxseed oil, beeswax and wine, beer, or rye whiskey. In addition, without additives, the gypsum was weak and prone to shrinkage and cracking. Aggregates were often added to increase strength and reduce porosity. Inorganic additives have been used to increase hardness, resistance and durability, and to retard the setting.

Sand was added as a filler primarily to reduce shrinkage, increase strength, improve performance and generally increase productivity. Most natural sands are at least 98% silica. The fine aggregate produced by crushing rock, gravel or slag is commonly known as produced sand. Marble powder was sometimes added as an aggregate because it allowed small parts to be produced. The purpose of adding organic matter was to improve workability, harden the mass, slow down the set or affect mechanical properties masses.

If you use metal beacons, then plastering will pass faster... However, after leveling the walls, the guides are removed, and the already plastered surfaces must be treated with mortar again.

The manufacture of lighthouses from a ready-made construction mixture is considered a rather laborious process, but after all the work is completed, there is no need to waste time on their extraction. Wooden guides are practically not used, because natural materials absorb moisture during operation, deform. Most often, lighthouses are used when decorating private houses from solid wood.

Selection of materials for applying decorative plaster with your own hands

Organic substances and weak acids can act as retarders. Accelerators are compounds that accelerate the rate of hydration and thereby cause the mixture to set or cure earlier. In medieval work, gypsum plaster was often added to lime as an accelerator of scores. Traditionally, additives have been used to provide water repellency such as waxes, fats and oils, or to trap air and thus improve kit such as urine or beer. For hand modeling, the ornament was added with plaster of Paris with a fire retardant such as glue, sour milk or wine to ensure long lasting work time; the sugary materials reduced the amount of water needed and slowed down the setting time, and the alcohol acted as an air invader.

When installing beacons, you must use the level

When installing beacons, you must use the level  Beacons are installed over the entire surface of the facade

Beacons are installed over the entire surface of the facade Types of decorative plaster

There are several types of decorative plaster. Silicate plaster is endowed with special strength, vapor permeability, durability. The composition includes potassium glass. Mineral facade plaster is resistant to mildew. Consists of cement, absorbent materials. Acrylic mixture is the most flexible facade plaster. The main element of the solution is synthetic resin. Silicone plaster for the facade has many positive qualities and excellent composition, but at the same time its cost is much higher than that of similar materials.

By application method:

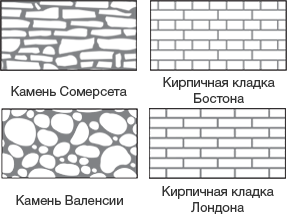

- pebble - warm plaster for the facade after grouting takes the form of small pebbles located very close to each other, sometimes the texture resembles a natural stone;

- mosaic plaster for the facade - the composition is particularly antistatic, hygroscopic. Transparent resin and fine mosaics in various shades allow you to create your original design facade;

- the most common cement plaster for facades has another name - bark beetle. A unique grooved texture is formed in the process of grouting a layer of mortar using a plastic flooring screed.

Bark beetle

Bark beetle  Kameshkovaya

Kameshkovaya  Mosaic

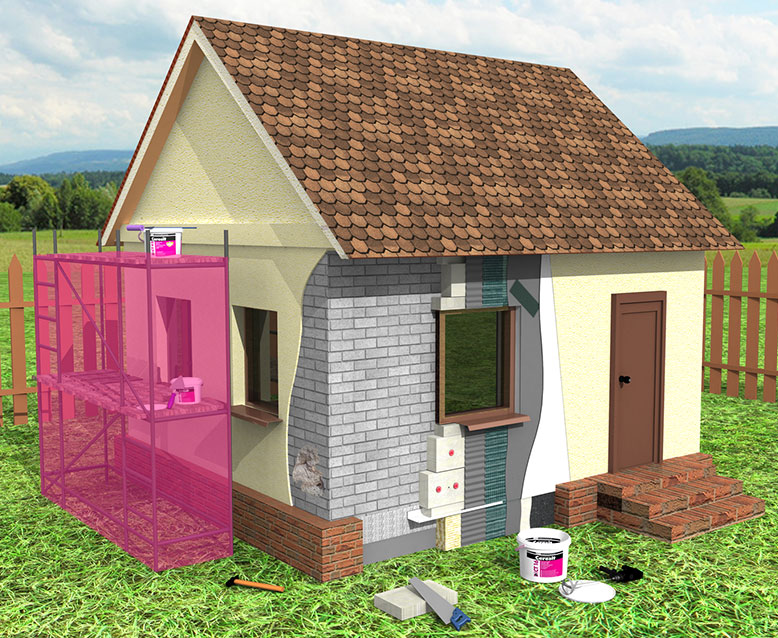

Mosaic In especially difficult climatic conditions, the insulated facade is finished decorative stone... Our photo selection contains the most popular ways decorative finishing residential building. Regardless of what the plaster consumption will be, the entire finish consists of several layers. In order to qualitatively plaster the base of the house, three layers of building mixture are applied to the surface of the wall: spray, primer and grout.

Surface spraying is the initial step finishing works... The main purpose of the spray is to provide a strong, durable adhesion to the plane of the subsequent plaster layer.

Spraying clay plaster

Spraying clay plaster This requires a structural mortar with a thick batter. This consistency helps the mixture to fill the formed cracks, wrinkles guaranteeing the strongest adhesion, allowing to contain all subsequent layers in the plaster. For concrete or brick walls the thickness of the layer can be up to 0.5 cm, and 1 cm of the mortar is applied to the wooden covering.

The spray applied to the plaster facade on the insulation must be quickly smoothed out. Most often this occurs after the formation of large bulging or hanging mortar streaks on the vertical plane. After a few hours, the mortar dries out. After the final drying of the first layer, proceed to the next stage of construction work.

Machine plastering and leveling

Machine plastering and leveling Application of the base coat

In the second stage of plastering work, the main function of leveling shallow cracks, chips, irregularities of the vertical surface is performed. Instead of a mortar, dry mixtures diluted to a sufficient density are used. The thickness of the soil can be up to 2 cm. When throwing in several layers of the mortar, the thickness of each subsequent layer should not exceed 1 cm. After the final application of the mortar, the vertical plane is leveled until a flat, smooth surface is obtained. In the process of work, you should use a falcon or half-grater, they may be directed in a different direction.

The more carefully each layer of the mortar is placed, the thinner the entire facade primer is.

All the elements that make up the priming solution are sieved through a coarse sieve, so rather large grains of sand can get into the mortar. In order to hide all cracks and roughness that have arisen during the priming process, a third period of finishing work is carried out.

Application of the main layer of facade plaster

Application of the main layer of facade plaster Grout

Wet facade plastering is impossible without the final stage of finishing work, for this it is necessary to remove the cracks formed during the work, smooth out all the irregularities. The mortar for grouting has a similar consistency to the spray mortar. However, in terms of its quality characteristics, it significantly surpasses the previous mixtures. All components are pre-sieved through a fine sieve. The thickness of the coating solution is about 0.5 cm.

The process of smoothing the unevenness of the plaster mortar

The process of smoothing the unevenness of the plaster mortar The finishing layer is carefully leveled with a trowel or trowel, when the horizontal surface grabs, it is rubbed with a construction trowel. First of all, circular grout is performed. To do this, with smooth counterclockwise movements, cut off the excess solution on the formed protrusions and rub it into the dents. The final step is to remove all circular marks from the surface of the plaster. Unaesthetic circles smooth out rectilinear movements construction float.

Grout should be done in a circular motion.

Grout should be done in a circular motion. Plastering the facade of a house takes a lot of time. To carry out the whole process in the shortest possible time, mechanized facade plastering is used. During work, specialists use a plastering station. High-tech equipment makes a batch and, under a certain pressure, applies the building mixture to a vertical or horizontal plane. The machine method can be used on all construction sites, the productivity is significantly increased, the consumption of the mixture is reduced. Despite all the seeming simplicity, the mechanical method of decorating the base of the house should be trusted by qualified specialists.

Video

The video tells how to properly plaster the facade of a building.

Photos of facades with applied decorative plaster

The selection of photos contains examples of facades decorated with decorative plaster.

In this article, you will learn:

In the modern market, decorative facade plaster characterized by an exceptional wealth of shapes, structures and colors. The finishing material is supplied on the basis of a binder (cement, silicone, silicate, acrylic). Quartz sand, granite, marble, sandstone and other rocks are used as fillers. Solid inclusions are responsible for the texture of the finish layer. The surface can be grained or grooved, and also create the illusion of finishing with natural stone, brick, wood.

Advantages of decorative facade plaster

The demand for decorative plaster for facade finishing is based on the performance of the material and the ability to improve the aesthetic appearance of the building. Among the advantages:

Preparatory steps required when applying decorative plaster with your own hands

In new construction, before finishing the facade, a technological pause is maintained, which lasts until the completion of the shrinkage of the building in order to prevent the formation of cracks and chips. the manual method will require a drill with a nozzle for stirring the mixture and a simple set of tools consisting of brushes, bristles, plastic, wooden and steel floats, spatulas, rollers, stencils.

The technology for making decorative plaster also involves leveling the walls. Preparatory stage:

- The walls are cleaned of bitumen and grease stains, saline areas, dust, dirt, mold, mildew.

- Fragile areas in the form of flaking and crumbling areas are removed.

- Aligning the walls of the base plaster mix... In hot weather, concrete or brick surfaces are moistened.

- The walls are primed. If the wall strongly adsorbs moisture from the applied materials, for example, made of foam concrete or gas silicate, 2-3 layers are required. Priming will increase the adhesion of the surface to the coating and will help to overcome uneven drying of the finish coat. In addition, it will serve as a protection against biological formations in the form of various kinds of pests and fungi.

- A technological pause is maintained. Drying time is determined by the primer manufacturer.

The plaster mixture is prepared according to the manufacturer's instructions. Mineral varieties need to be diluted with water and stirred, while acrylic, silicate and silicone mixes are supplied as ready-to-use mixes.

The technology for performing decorative plaster at the last stage

Techniques for applying decorative plaster allow you to create a grainy or grooved surface, imitate the texture of wood, granite, sandstone and other materials. The choice of tools depends on the task at hand. Rollers, graters, spatulas, stencils will become indispensable helpers in this matter. When carrying out work, it is necessary to strictly follow the recommendations of the manufacturer's plant on the rate of mixture injection, as well as maintain technological pauses. Among the favorable moments for applying the finishing layer, it can be noted:- Air temperature 5⁰С – 25⁰С.

- Humidity up to 70%.

The application of pebble plaster is carried out with continuous strokes. The thickness of the layer is dictated by the size of the filler grain. The size of the solid fraction will serve as a limiter for the spatula. When a flat area with a small amount of scratches is formed, grouting is started:

- The furrowed pattern "bark beetle" is formed by smooth horizontal, vertical or zigzag movement of the plastic float. Smooth and measured movements of the hand will allow you to get a texture that is uniform in the pattern. To connect areas without a visible seam, the area to be treated is not rubbed by 10 cm. It is started to grout after plastering the next area.

- The "lamb" texture is obtained by a circular motion of the hand with a grater or surface treatment with a roller, which allows the stones to be evenly distributed over the area. At the final stage, you can paint the finishing layer if you have not used a tinted mixture.

Graffito plaster is a mixture that allows you to model the texture by applying and processing several layers. First, a tinted layer is applied. Then 2 or 3 more layers are applied. After a few hours, a cut is made on the partially hardened layer, which exposes the lower layer, which creates a relief ornament.

Techniques for applying decorative plaster using rollers, dies and stencils

If attracted by a needle-like structure or a pigtail shape, a base layer is thrown onto the wall. When it dries slightly, after 15 minutes a second layer is applied, which is processed with a rubber structured roller. The drawing can be printed while the layer is pressed through with your finger. It is convenient to apply the texture with the assistance of an assistant. One man puts a matrix on the surface, and the assistant presses on it, imprinting the image. Sagging is removed with a soft sponge.

puts a matrix on the surface, and the assistant presses on it, imprinting the image. Sagging is removed with a soft sponge. In a similar scheme, rolled-up silicone matrices are used. You can create the texture of wood or stone by gradually unrolling the roll on the wall with a slightly tacky finish layer.

A self-adhesive stencil is used to simulate masonry. First you need to apply a primer, tinted to match the color of the seam between the stones. Then pause to dry the primer. A stencil is glued to the wall, on top of which a finishing layer of 2 mm is applied, and the surface is rubbed. At the first signs of setting of the decorative plaster, the stencil is removed.

For work, use a tinted mixture or paint the surface after completion of work, when the decorative layer has already hardened.

Selection of materials for applying decorative plaster with your own hands

The choice of a suitable decorative plaster depends on the desired texture, the requirements arising from the specific type of building, the economic possibilities of the owner of the house. Also, do not forget that the facade is an external enclosing structure and provides protection from weather conditions, therefore, it is an investment in the future, which will bring savings in the form of redistribution of money for heating. Before choosing a finishing layer, all factors must be considered.The choice of decorative plaster for the facade involves taking into account the preparatory work so that the consistency of all layers is flawless. Full compliance is possible if all materials are supplied in the same brand system. The manufacturer's company should be chosen for the duration of its work in the market and impeccable reputation.

The brands, which have been present on the construction market for a long time, give detailed recommendations on the production of work and the volume of materials per square meter, as well as provide consulting services. On the websites of manufacturers of decorative plaster always for additional information. It is also worth remembering that "cheap" is not always "better." It is not worth saving on materials so that you do not have to redo the work performed.