Facing the facades of residential buildings is carried out not only to make the building look attractive on the outside. For the most part, this event is carried out in order to protect the wall material from external factors. Under the influence of snow, rain and wind, walls can quickly become unusable, and many homeowners decide to clad and provide protection and insulation to the walls. You can contact the company METSTAL - our experts will help you find the best solution to give your house a beautiful appearance.

Selection and comparison of materials for house cladding

The materials from which the walls of houses are built have the ability to absorb moisture - some to a greater extent, others to a lesser extent. In winter frosts, the accumulated water turns into tiny ice crystals, which gradually destroy the walls. As a result, mold can form inside, and the house itself becomes damp and cold.

Which of the well-known materials is more suitable for lining the building, the owner of the property decides, depending on his preferences and capabilities. There are many options on the construction market, the most common of which are the following:

- Decorative plasters.

- Brick and tile finishing.

- Siding.

- Porcelain tile.

- Natural and artificial stone.

- Front cassette panels.

Each of these materials has both advantages and disadvantages. It is worth noting that the price of such materials can differ quite seriously. designing building or Finishing work, it is necessary to determine the budget for materials in a timely manner, as well as familiarize yourself with their characteristics. Perhaps the desired type of finish is categorically not combined with the material of the walls, and you will need to look for a more suitable solution.

Plastering is considered the most ancient type of finishing. Nowadays, a lot of plasters have appeared that are suitable for finishing different walls. Plaster compositions are practical and allow you to create an aesthetically pleasing coating that has good waterproof qualities, is resistant to temperature extremes, and applying building mixtures to the surface is not particularly difficult.

No less popular is the cladding of the facade of the house with wooden materials, stone, and decorative panels. Using the services of METSTAL specialists will help you solve the problems associated with cladding. In case of difficulty, you can seek advice.

Facing the facade of the house with wood

Wooden materials outwardly have a special warmth, the lines on them form a beautiful natural pattern. Each of the breeds has an original shade that changes under the influence of rain and sun. Most modern designers prefer to choose wood that has been artificially aged, with a matte lacquer finish for their projects. Wooden materials look impressive against the background of glossy metal and plastic surfaces, shining glasses.

Consumers are offered different options for natural wood cladding:

- Board ship.

- Planken.

- Block house.

- Panels slatted or made of wood.

- Massive boards.

Facing the facade of the housewood materials helps to keep the building warm, and the walls acquire the ability to breathe. The high vapor permeability of the finish allows moisture to freely escape from the room. In addition, the use of wood cladding helps to maintain a healthy microclimate inside the house.

Wooden materials are well combined externally with stone, and with a plastered surface, and with brick walls. When carrying out high-quality processing and observing the rules of operation, wooden facades have been quietly serving their owners for decades. To enhance the performance of natural wood, it is impregnated with special compounds that protect against woodworms and fungal diseases.

Products obtained by pressing are distinguished by greater density and strength. Mixing of raw materials with various components is also carried out, and gluing strips of material like a sandwich reduces its hygroscopicity and helps to reduce corrosion if wet. Natural and synthetic coatings are produced in such a way that the natural beauty and pattern of the wood is preserved.

Having carefully worked out the design, an ordinary brick building can be turned into a real tower if wood materials are used for decoration. When finishing with panels and boards, metal elements are used for fastening. Massive boards, planken are installed with the obligatory creation of a ventilation gap. The ship board and lining are mounted with an overlap. Other products are connected using grooves specially provided for this.

Planken is a special type of finishing elements that will perfectly protect the walls of the building from the wind. It is installed on ventilated facades, leaving free space between the outer wall and the insulation. This space provides free exit of moisture from the room to the outside. The boards are made with small gaps that compensate for the expansion of the material and help improve the ventilation effect.

Lining - a board for sheathing, to facilitate which a lock is made along the side grooves. It is fastened with a herringbone or "butt". The advantages of lining are in ease of installation, convenient fastening due to locks, there is no serious deformation due to frost exposure. Thanks to the special design of the elements, they will not warp from moisture, grooves are made on the elements that help ensure ventilation, and the special processing of the lining repels moisture.

The block house has an oval front part. The elements are made of solid boards, imitating rounded logs. Buildings lined with this material give the impression of strength, solidity, good prosperity of the owners.

Facade boards are also made from sawdust mixed with composites and various additives. Their appearance is very close to natural materials, but the vapor-permeable qualities are somewhat worse. In comparison with natural products, the material with the addition of composites is less prone to burning, mold and insects do not form in it, and the rays of the sun and rodents do not spoil it.

Facing the facade of the house with stone

Facing the facade of the house with stonedoes not lose relevance for many years. Stone coating helps to increase the life of the external walls of the building, makes the house original, attractive in aesthetic terms.

A variety of elements can be used for facade cladding - limestone strips, small tiles and whole stone slabs. Stones intended for decoration have a unique beauty of textures and natural patterns. Thanks to the cladding made using natural stone, any building stands out noticeably from others.

The finishing stone has high performance, it is not afraid of humidity, sudden changes in temperature, exposure to sunlight and mechanical damage. Such wall protection helps to significantly increase the life of the building. Finishing can also be very economical - for those who are attentive to expenses and are not in the mood to spend significant cash, you can offer an artificial imitation of stone. Products retain all the properties of natural stone, repeat it appearance but the cost is much lower.

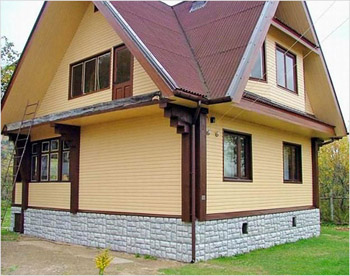

When finishing the surface of the walls with stone, there is no need to cover the entire surface with it. Combinations of stone and plaster, stone and wood look original. For example, you can cover the upper segment of the walls with plaster, and frame windows and doors with stone elements, or arrange stone mosaic panels against a plaster background. The light shades of the stucco surface provide a pleasant contrast to the cold and austerity of the stone cladding. You can decorate buildings in the local area in a similar style.

Various unusual combinations can be used in design compositions, the space for decoration is divided into vertical and horizontal zones, for which various types of stone are used. Finishing will cost less if it is done by hand, but in the absence of experience, it is better to look for intelligent professionals. Properly executed stone cladding will give the facade of the house a neat and original look.

Facing the facade of the house with plastic panels

Facing the facade of the house with panelsmade of plastic is convenient and simple. The material has numerous useful properties, in addition, this finish helps to keep the house as warm as possible. This is a big plus - there is hardly a house owner who would not like to reduce the cost of maintaining it.

Plastic facades can be used for finishing hinged and ventilated facade systems. There are many advantages of this material:

- The walls are protected from external natural influences.

- Through the use modern technologies plastic is not subject to rotting and fading.

- Material with the same effect is used for finishing new buildings and old houses.

- Ease of installation, low cost, variety of colors and textures.

The composition, which is used to cover the elements of the product, provides reliable protection against precipitation and wind. They are able to withstand many cycles of defrosting and freezing and not lose their working properties. To create a finish, laborious surface preparation is not required - the creation of a crate is suitable, with the help of which the base is leveled. When using facades made of plastic elements, it is possible to additionally lay an insulating material between the cladding and the wall.

Facade work using plastic cladding panels can be performed at any time of the year - this is another advantage of them. You can purchase elements of the desired color and texture for finishing, which will give your home an aesthetic, ennobled look. There are even products with drawings - their use for decoration helps to achieve very original design solutions.

Application plastic panels it is easy to install - even an inexperienced finisher can carry it out. The benefits are as follows:

- There is no need to carry out long and laborious measures to level the walls.

- It does not require the creation of expensive and time-consuming fastening systems - ordinary self-tapping screws and staples are suitable for fixing.

- Panels can be installed both horizontally and vertically.

- Installation can be carried out in any weather, when it is convenient for the customer. Most finishing materials need to be fixed only under certain weather conditions.

Panels made of smooth plastic are less susceptible to dirt, they do not require special time-consuming maintenance. Choosing plastic panels, you get an excellent low-cost solution, durable coating with good performance.

Facing the facades of houses with tiles

Tiles and bricks are another option for facade cladding. The shapes, sizes and textures that modern manufacturers offer to consumers can help bring the most original ideas to life; any building with such a cladding acquires individuality.

Facade tiles are a universal material for making cladding, which has good decorative properties and improved performance. Many technologies have appeared for the production of facing elements, thanks to which the consumer is offered a large selection of products with different color and texture solutions.

Before facade tiles appeared, buildings were sheathed with wooden materials. Plastering or cladding of the facade of the house with bricks was also carried out, and for the respectability of the appearance, it was customary to finish using natural stone. Today, facade tiles are preferred for decoration due to its special advantages:

- Tiles, being subjected to pressing and exposure to high temperatures during manufacture, acquire high strength.

- The material does not absorb water, has good resistance to chemical compounds and does not wear out over time.

- Installation of plates on the wall can be done without unnecessary difficulties.

- Facing the facades with tiles allows you to save a little on the construction of the foundation - the material is quite lightweight and does not require a powerful base.

- When performing cladding, it is possible to enhance the thermal insulation properties of the building, level the surface of the walls, and hide visible flaws made during the construction of housing.

- Tiles can be combined with other finishing materials.

Among the various facing materials, several types can be distinguished.

- Stone slabs look attractive and noble in contrast to imitation. Granite and marble are most often chosen for cladding - they are able to emphasize the status of the homeowner. Since such a facade is distinguished by a high price, technologies have been developed that allow imitation of natural stone materials.

- Ceramic granite tiles - it is made from a mixture of granite chips, quartz and spar, with the addition of expanded clay and binders. In the manufacture, pressing and firing are used, resulting in a monolithic material. Porcelain stoneware slabs are often used to equip a ventilated curtain wall.

- Concrete slabs are made of quartz sand with additives for strength and water repellency, with an adhesive composition. After installation on the facade, it is useful to supplement the material layer with sealant and renew the layer about twice a year.

- Ceramic and clinker tiles are mounted on the facade according to the same principle as bricks. Facing is not particularly expensive, it turns out to be more lightweight, installation is carried out using simple technology. Clinker tiles are more frost-resistant and durable. There is also such a variety of ceramic products as terracotta tiles made from natural raw materials - clay is used for its manufacture.

The outer layer of the building can be made in the form of brickwork. Facing the facade of the house with brick will require special skills - you should not take on this work yourself, since it is necessary to perform rather labor-intensive operations. Carrying out such a finish can revive even buildings built many years ago. The house takes on a wonderful appearance and stands out noticeably from the outside among the surrounding buildings.

To finish with such materials, you must first thoroughly clean the rough surface. It is leveled, the seams are plastered, noticeable damage. Thermal insulation material can be laid between the finish and the draft wall. When using bricks, it is necessary to strengthen the foundation, since the outer layer is quite heavy. Even when facing in half a brick, the pressure is significant.

The best material for cladding the facade of the house

Facing the facade of the house - which material is betterfor this? Each owner of a residential building decides this issue independently. When choosing, it is necessary to take into account the material from which the building is made, calculate the increase in load, evaluate the feasibility of the selected type of finish. It is also necessary to take into account the economic component, since there is nothing pleasant in the fact that, due to a lack of finance, repair and finishing work is delayed for a long time.

Each of the materials used for finishing has its own advantages and disadvantages. Therefore, to begin with, you can decide what specific type of building you want to get, and then move on to comparing different materials. Proper installation of a ventilated facade structure using the services of METSTAL will help you get high-quality cladding that will serve you for many years without loss of performance.

Arrangement of a ventilated facade with the use of finishing provides the building with protection from condensation, fungus, mold on the walls. The services of METSTAL specialists will help reduce the cost of cladding. You get a beautiful, renovated building, which is literally transformed - you just need to carry out the finishing with the selected material.

By implementing modern facade decoration, you create your own individual style. beautiful facade will always make a great first impression on a client or partner. And in our age of technological progress, the demand for finishing the facades of buildings is becoming more and more popular every year.

Outdated typical and gray facades have lost their relevance and become unattractive, so many owners of offices or office buildings have already appreciated the original and attractive design of building facades. This is confirmed by the growing number of buildings with interesting and decorative facades on the streets of the metropolis. Modern facade decoration requires professional intervention, but this issue also needs to be approached creatively. Together, these two conditions will contribute to the fact that your facade will stand out brightly against the background of neighboring buildings. Indeed, today new trends in the construction of facades are constantly appearing, such as hinged ventilated facades.

Hinged ventilated facades are easy to manufacture, and their installation does not take much time, being very easy to implement. You can also use light facade siding, paneling and more.

In any case, if you are seriously thinking about finishing the facade of a building, the Remont-Uyut company will be able to realize any of your ideas, from design to full-fledged finishing. After all, we offer you a huge variety of methods and types of facade finishing, as well as installation of decorative facade elements and much more. You can learn more about the options and methods for finishing facades by calling the numbers indicated on the website. Our qualified masters will answer all your questions, advise if necessary suitable option finishing the facade of a building, as well as talk about the timing of work and cost.

Why do you need facade decoration

So why do we need facade decoration? Measures for finishing the facades of offices is a complex of operations aimed at increasing the artistic value of the object. After all, the “face of the organization” should always look prestigious, attractive and original, as well as be memorable and correspond to the type of activity of the company. That is why we provide a set of activities aimed at raising the status of the organization and attracting more customers. The most requested design requirements here are:

Business strict style;

Classic finish;

The latest solutions for plinths and facades.

Technological features of facade decoration

Absolutely everything, from the outer walls of the building to its basement, must be combined and functional. Due to the combination of these features, the finishing of building facades is a complex service. To increase the original design, the following technologies are used:

Wet or ventilated models of facade systems;

The use of translucent structures for the organization of elite glass vestibules, main entrances, passages, stained-glass windows and panoramic glazing (including deaf);

Facing various types stone - clinker, brick, natural or artificial stone.

Often, these technologies are used in combination and integrated into the architectural style of the building to greatly increase the attractiveness of the façade. The so-called wet facades are a democratic solution, they have a low cost and ease of implementation, one has a low resource. This model is usually used for finishing the facades of shops, beauty salons, as well as offices of medium and small businesses.

Panoramic glass showcases already belong to the elite decoration of the facades of large offices, municipal buildings and multi-storey buildings. This technology always guarantees high originality and an exclusive yet versatile architectural style that blends with the different surrounding buildings.

The most demanded and popular facade cladding technology is ventilated facade systems - they are chosen by about 70% of users. Such systems have great variability due to the huge range of facing materials and elements:

Composite panels are used for classic business style;

Elegant finishing of facades of diversified organizations - linear panels;

Fiber cement elements will help to achieve grace and nobility of forms, as well as not have restrictions on the configuration of the walls;

Terracotta and clinker are used to achieve classics combined with durability and originality;

Also, grace and originality will give a stone - porcelain stoneware, natural or in artificial modifications.

The choice of method is carried out during the design. A big advantage of ventilated facades is the ease of dismantling, if necessary, and replacement of the cladding.

The cost of finishing the facades of buildings

The company "Remont - Uyut" immediately carries out a set of measures for the construction and decoration of offices and office facades, so our prices are very democratic. The final cost of the work will depend on the chosen technology and the required level of originality. In the case of redevelopment and the manufacture of translucent entrance groups on light metal frames, it is necessary to issue special permits. Due to this, both the terms of work and the price can increase.

The most inexpensive options for finishing the facade are “wet” technology, siding and tiling walls. At your request, our experts will help you choose a worthy replacement for expensive materials among budget linings. As a result, the customer receives an attractive facade with walls protected from bad weather and ultraviolet radiation.

The cosiness and comfort of a private house or country cottage largely depends not only on internal repairs or the thickness and reliability of the walls, but also on the external cladding. Finishing the facade is the final stage in the repair of the house, but an important one. Sheathing of external walls may include several stages, namely, insulation and decoration of the building. In addition, if you plan to finish the facade yourself without the help of specialists, then you should know certain rules and standards for such work.

V last years market building materials offers the consumer an extensive selection of products for building cladding. Options for finishing the facade of the building when using:

- a natural stone;

- fake diamond;

- decorative brick;

- wall plastering;

- clinker tiles;

- facade cassettes.

Consider in more detail each of the options for exterior decoration of the house.

A natural stone

Facing the facade of a building using natural stone is an expensive pleasure, and before you decide on such a finish, you should think carefully. Stone finishing can be done with materials such as:

- granite - is the most expensive material, but its beauty justifies such costs;

- finishing using shell rock and sandstone;

- limestone cladding;

- Dagestan stone.

In most cases, Dagestan stone is used to decorate the building with natural stone. This material is environmentally friendly and includes limestone, shell rock, sandstone, and dolomites. Such a stone has a large number of different shades.

Exterior decoration with Dagestan stone

With the help of shell rock and limestone, decorative wall decoration is possible, as well as the preparation of various compositions. In addition, these materials are the most practical. This type of stone, which consists of mollusk shells, lends itself well to processing, so it is very easy for builders to work with it.

Natural stone can be used not only for facing the exterior walls of the house, but also for the manufacture of columns, arches or even railings. Such a natural material retains heat well in the house in the cold season, and cools it down in summer.

However, it is worth remembering that you need to deal with the decoration of the exterior walls of the house using natural stone in the fall or spring. The air temperature should not be very low or, on the contrary, high. At high temperatures, the mortar with which the stone is attached will not give a good grip, and at low temperatures it will quickly harden.

Fake diamond

This type of finish has become more and more popular over the years. Fake diamond- This is an alternative to natural material, besides it is much cheaper. The manufacturing technology of this material involves the use of white cement, stone chips, pigment, and quartz sand. The artificial material is lightweight, so its installation will be easier. In construction stores, you can see a special dry mix for sale, from which similar material can be made already at the construction site. For this, only special forms are needed, into which the prepared solution is poured.

The building is clad with a stone substitute, using cement, a plasticizer (added to the cement mixture to make it more elastic), and in some cases coloring pigments can also be used. Coloring pigments may not be used if the owners of the house are satisfied with the color of the artificial stone.

decorative brick

Simple brick is widely used in the construction of buildings and structures, but when there is a question about finishing the internal walls of the building, then in this case decorative brick comes to the rescue. This material is represented by the widest range of different colors. In addition, the decorative finish with such bricks is very durable and reliable, even after decades the facade of the building with this material will not lose its appearance and shape.

Such material is produced both in Russia and abroad. Therefore, when buying it, consider these aspects. The material brought from abroad costs several times more than the material made in Russia. When buying, it is also worth considering the density of the building material and its marking.

Wall plaster

Finishing the exterior walls with plaster is the most economical and practical solution. But not everyone knows that several types of plaster can be used for the facade of a building:

- mineral;

- acrylic;

- silicone;

- silicate.

Building finishing technology mineral plaster is the most common and economical. For greater strength, special substances can be added to cement-based plaster, which enrich it with trace elements. One of the disadvantages of this plaster is the minimum number of shades, so after applying it to the wall, the building is painted.

Combined finish: plaster and artificial stone

Acrylic plaster is sold ready-made, it can be immediately applied to the wall surface. Recently, the most common acrylic plaster is the bark beetle, the application technology of which makes it possible to obtain a finished surface that imitates the corroded surface of this insect.

Silicone plaster is one of the most expensive, this is due to its high quality, as well as a host of positive characteristics. Applying a silicone finish to the wall helps protect the building from the effects of mold, mildew and external factors nature for many years.

Silicate plaster is made on the basis of liquid glass, which makes it permeable, so moisture does not accumulate on the walls, but comes out. Due to its good plasticity, it is easily applied to the surface.

siding finish

Siding is pretty common. This material is practical, resistant to moisture, non-flammable and non-toxic. In addition, for facing the building with siding, the budget will require a minimum, and this is an important issue in our time.

You can sheathe the house outside with vinyl siding, metal, and cement siding. Finishing the building with vinyl panels will give the house an aesthetic and sophisticated appearance, as they can mimic the look of natural stone. Facade cladding with metal panels will cost more, but will be stronger. Metal siding, like vinyl siding, can imitate natural stone or wood. Sheathing buildings with cement siding is often used in places with problematic climates ( low temperatures), as it is the most durable.

Clinker tiles

Finishing options for buildings using this material are popular in many countries. This material is quite durable and surpasses natural stone or brick in many of its characteristics. The composition of this material includes only natural and safe substances for human life. Clinker tiles withstand large temperature fluctuations, as well as precipitation and sunlight. The building materials market offers its consumer a large selection of this material of various colors and textures.

Materials for finishing facades can be very diverse. These include: clay bricks, ceramic tiles, all kinds of wood and stone. But life changes, and progress does not stand still. Such modern materials for finishing buildings are available on the construction market, which carry two important factors.

- Firstly, with the help of these materials, it is possible to make the lining of the structure.

- Secondly, by means of such materials it will be possible to insulate absolutely any building.

By the way, this can be done in a short time, which, in turn, can minimize labor loads. This fact leads to a decrease in the price per 1 sq.m. housing. If you want to know how the decoration of the facades of houses with modern materials looks like, then together with the site we will give you examples and show interesting photos.

Types of facade panels, their advantages and disadvantages

In most cases, facade panels act as elements of the system of ventilated facades. One panel, as a rule, consists of insulation, decor and frame. Its main role is that during installation, a small space remains between the insulation and the wall of the house, which will protect it as much as possible from the accumulation of moisture in it, and thanks to this, thermal insulation will be created.

So: The production and manufacture of building materials intended for facade cladding has now increased several times, as the demand for them is constantly growing every day.

The range of these materials is quite large. It can be a multilayer material, wood, metal-plastic, as well as all kinds of imitation. For this reason, it is not easy to make the right choice of a particular product.

Various materials for finishing the external facade of buildings are used for cladding indoors. These materials are sized design features and special installation methods. But there is one important factor that unites them into a single whole - a beautiful view of the outer part of the facade, which is inherently the most durable.

Coated metal panels

- This type of panels is made from steel sheets having a thickness of 0.6 or 0.7 mm, on the outer part of which a polymer coating is applied.

- This material, intended for finishing facades, will not only be durable and strong, but also with the help of it an unforgettable, beautiful design will be created, since the polymer coating on the panel can look like an original relief or have bright colors.

- A large number of various reliefs and configurations helps to combine the cladding panel in poured versions with each other, and to finish the facade according to any chosen form. Joints between panels may vary. This, in turn, will help to adjust the cladding to the required parameters of the facade without any problems.

- In a specialized store that sells these materials, at the time of purchase of the panels, you will be given instructions for installing them.

Steel panels of the PF type have fasteners of hidden and visible type. The manufacturer of these panels is engaged in their production for individual orders, in the event that it is necessary to make a panel in the form of a triangle or trapezoid. These panels, as a rule, differ in their appearance and can be either flat or embossed, imitate wood or have ribs. Based on this, the cost of such non-standard panels will be higher than that of conventional ones. When installing metal panels, the same components are used as when facing the external facade of buildings with siding. For more detailed information on this topic, watch the video and find the articles you need.

Fiber cement textured panels

If you do not know how to finish the facade of the house, then you should remember all the options for materials that can be freely used for this purpose. It is worth saying that fiber cement panels are often used for facade decoration. The main advantage of such textured panels is that they can perfectly imitate all kinds of materials intended for facade decoration. For example, these panels can replicate the look of tiles, or masonry.

- The production of these panels is made from cement with the addition of loose cellulose and synthetic fibers. In most cases, the outer layer of these panels is ceramic. Based on this fact, this facing material in its internal structure has excellent durable properties, and during operation for a long time does not change its original appearance. It is also not subject to high temperatures, it is refractory.

- A huge variety of applications for this material. Textured panels can be used not only in facade cladding, but also in the lower part of the basement, the interior of buildings, etc.

- Very often, the top layer of a fiberboard is made of polyurethane, granite or marble chips, and there are also options with an acrylic coating. The manufacturing technology of such tiles is as follows: First of all, all the components and ingredients necessary for the production of tiles are balanced and mixed together. Thus, the desired solution is made. The resulting mass is sent to the extruder for further molding of products and giving them the desired shape. Further, the process of firing and processing with a special protective primer and the application of a decorative coating takes place. In the final form, beautiful panels of excellent quality are obtained.

OSB boards

From this article you will learn how the decoration of the facades of houses with modern materials should look like. Here we present modern materials that should be used in such work. For finishing the facade, you can freely use OSB-plates. The structural properties of OSB boards are very similar to the structure of the facing materials described above. They are also resistant to moisture.

On the shelves of building stores, this material comes in the form of large sheets. And their further cutting can be done independently. You can also decorate them easily. Below we can see what beautiful options for facades can be obtained as a result when finishing them with wood-based panels. We also gave examples of photos where OSB boards and decorated panels were used for facade cladding.

What are thermal panels

Thermal panels are a unique material that can be freely used to decorate the facade of a building. Therefore, if you are concerned about the question of how to finish the facade of the house inexpensively, then such material will be the best solution in such a situation.

- In the event that it is necessary to provide for a ventilated facade during the exterior decoration of the building, then here you need to think in advance about the use of insulation. If we are talking about thermal panels, then in this embodiment we will not need a heater, since this material already has thermal insulation properties. In addition, thermal panels have a decorated outer layer. Based on this, you also do not need to spend money on the purchase of materials necessary for facade cladding.

- The production technology of thermal panels consists of the following stages: The main material for the manufacture of these panels is polystyrene. It is first foamed, and then the granules are dried. First, the necessary material is placed in the prepared block forms. It will later form a decorative layer. For example: stone or clinker tiles.

- The next stage of work is immersion in the form of granular insulation. Next, it is heated with hot steam. In the process of heating, the granules begin to melt, they are pressed with tiles. Then the finished panels are cooled and left for a day. The result is compact products that can be perfectly joined together.

- These panels have a very low weight, so you can solve several work tasks at once.

Finally

For warming and finishing a small house, a minimum of time and effort will be required. But there is one small drawback. After all, the more compact and smaller the cladding panels, the more time and effort it will take to carry out external finishing work.