Facing brick facades invariably attract admiring glances. Every developer knows: building solid walls is not enough. They need to be finished with such a material that it helps to get a triple benefit at once: it insulates, strengthens and decorates the building. Facing brick fully meets these requirements. It is able to reliably protect external walls and increase their bearing capacity.

- facing;

- front;

- facial.

All this is one and the same material that has the properties necessary for a high-quality building finish. From these stones, the outer layer of the wall is built, which is in direct contact with the environment and experiences all its adverse effects. Therefore, special requirements are imposed on the technical characteristics of these products.

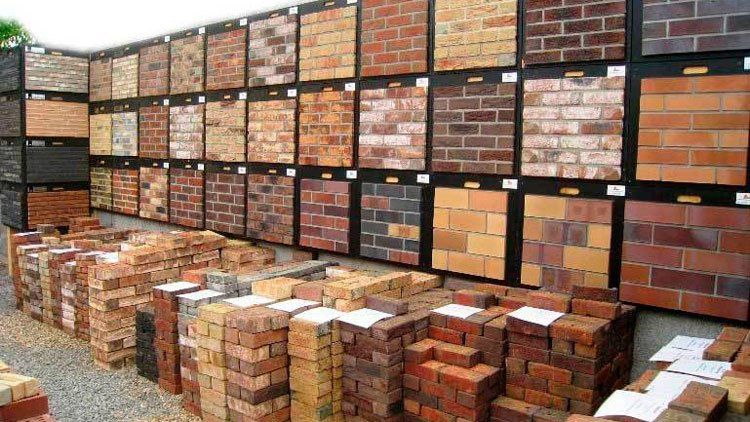

Depending on the type of materials used in the manufacture and the production method, several types of facing bricks are distinguished:

- clinker;

- ceramic;

- hyper-pressed;

- silicate.

These products have different performance characteristics, but there is one common point: they can all have a traditional parallelepiped shape or figured. Bricks of the second type are called shaped. Each of the options has its own production standards, which all manufacturers adhere to.

Traditional bricks are:

- single;

- one and a half;

- thickened;

- double.

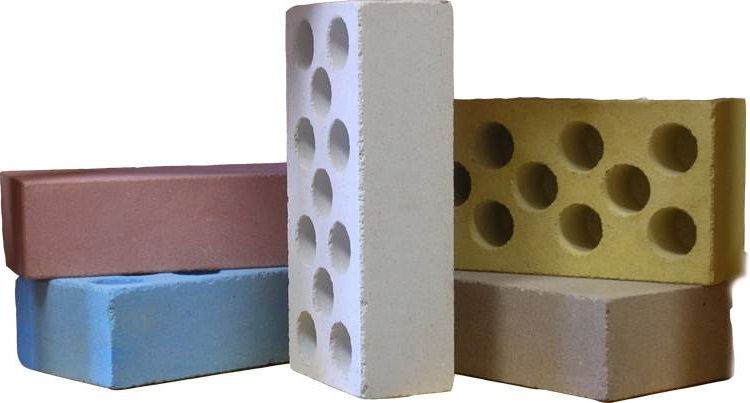

Each of the listed products can be solid or hollow (hollow). Stones of the second type can have different hole shapes and different numbers.

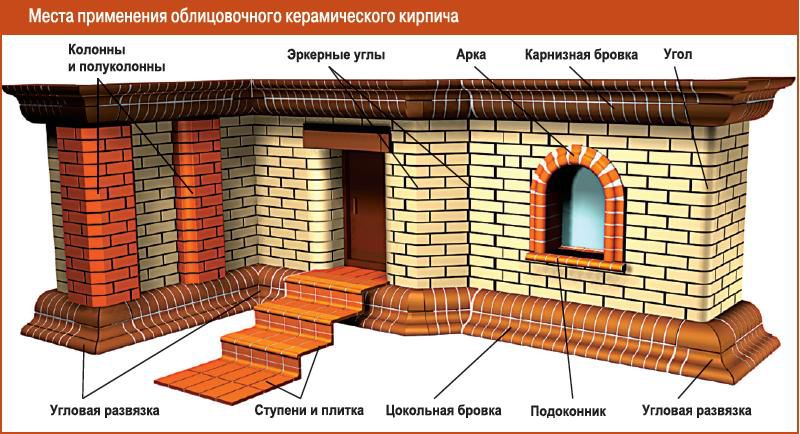

Shaped bricks impress with their striking appearance. With the help of these building stones, the most original ideas of architects and designers can be realized.

Manufacturers offer shaped bricks of the following types:

- trapezoidal with beveled ribs;

- twisted;

- wedge-shaped;

- with a textured front surface (under chipped or natural stone).

The spectacular appearance of curly stones largely depends on the method of decorative processing of their surfaces.

Three technologies are used:

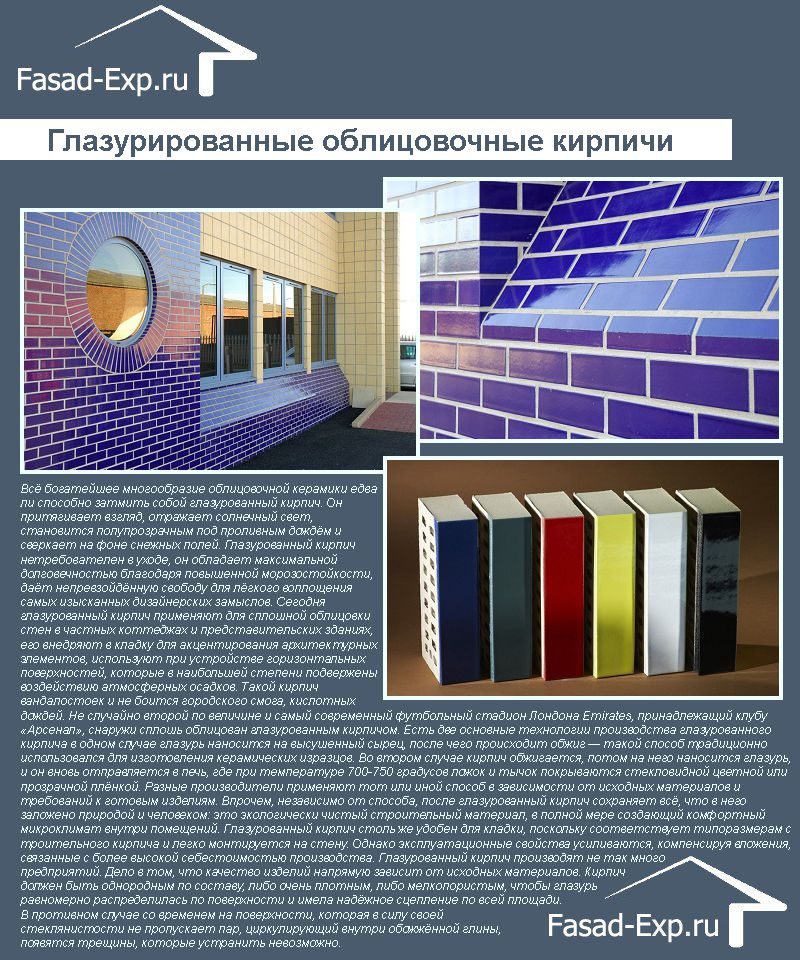

- glaze;

- torquetting;

- engobing.

For facing the facade of a residential building, engobed bricks are more suitable. They have a matte surface and, due to the production method, have a lower thermal conductivity coefficient. The engobing technology provides for the application of an additional layer of clay to the raw stone. It is he who makes the product "warmer".

Engobed bricks

Glazed bricks have a glossy finish. The color range of such stones is very wide. Glazing can be applied in two ways: on a raw or finished product. Regardless of the methodology, the quality and appearance of the product will be the same.

Torketing is the process of applying mineral chips to the front surface of a brick. After firing, the product acquires a beautiful relief texture. Such stones are often used to emphasize the architectural elements of a building: arches, entrance lobby, window openings, cornices.

Ceramic brick, shotcrete with mineral chips.

Pros and cons of clinker bricks

Clinker brick is one of the best representatives of facing bricks. Such interdependent characteristics as water absorption and frost resistance are at its best. These stones can withstand up to 300 freeze-thaw cycles (frost resistance coefficient F300). But the thermal conductivity is quite high: 0.7 W / (m * ° C). Durability - at least 100 years.

Among the features of this material is the duration of its laying. This is due to the low coefficient of water absorption. The stone slowly absorbs moisture from the solution, so working with it requires a certain skill.

The disadvantages of this material include the fact that even in one batch of clinker bricks, products of different shades are often found. This greatly complicates the masonry process and increases the construction time. Workers have to choose stones of identical color and distribute the darkest shades on the wall in the most beautiful way.

Clinker brick requires masonry with special mortars. The cost of these compounds is high, as is the price of the material itself. There is a possibility of laying on a cement-sand mortar, but you need to know the recipe for preparing the mixture and be able to work with it. The clinker brick "floats" on an ordinary mortar.

Pros and cons of ceramic facing bricks

Ceramic bricks are distinguished by a variety of shapes and colors. The undoubted advantage of these products is environmental friendliness. At first glance, these stones look fragile due to the large number of voids. But this is a misleading impression. Ceramic bricks are highly durable.

The main disadvantage of these stones is errors in the geometry of the shape. This complicates the masonry process, as it is necessary to check the correct size of the stones. Another drawback is limestone inclusions, which subsequently absorb moisture and begin to stand out on the surface of the wall with their more saturated color.

Pros and cons of hyper-pressed bricks

The composition of hyper-pressed bricks includes shell rock, cement, and special additives.

The advantages of this type of stones:

- perfectly flat geometric shape;

- the same dimensions for all products of the same type;

- variety of colors;

- pliability in processing (easy to saw);

- high strength 150-300 kg / cm2;

- water absorption 5-6%;

- frost resistance F150;

- a wide range of shaped models.

Hyper-pressed bricks have practically no drawbacks. The disadvantages include a large weight (4.2-4.4 kg), which affects the cost of transportation and the labor intensity of the masonry.

Pros and cons of silicate facing bricks

Silicate bricks are characterized by regularity of shapes and high strength. Among the advantages of this facing material is the ability to withstand high temperatures, ease of processing, high sound insulation characteristics, and an affordable price.

Flaws:

- high thermal conductivity, which increases with moisture;

- large weight (single 3.3-3.6 kg, one and a half - 4-4.3 kg);

- monotony of colors;

- high moisture absorption coefficient;

- lack of shaped models.

Should I buy hollow facade bricks?

The peculiarity of most affordable stones of this type is that they have the maximum possible number of voids. This is due to the peculiarities of the manufacturing technology and the desire of manufacturers to save money. For the same purpose, they (manufacturers) often make only two edges of the product face: one spoon and one butt. But such a decision is justified, since the stone is turned outward only with one side of it. The size and shape of the voids can be different, respectively, the weight of the bricks is also different.

The veneer is usually thin. Since there is a stone of a porous structure with many voids behind it, the face layer does not receive enough heat from it and is often overcooled. This leads to the appearance of microcracks. Water penetrates into them, which periodically freezes and thaws. The wind and the rays of the sun make their contribution to the destruction process. All this leads to dire consequences for the building. Therefore, you can often see facades, the front brick of which is partially destroyed.

The Europeans were the first to understand the disadvantage of such building stones. They decided to halve the width of the product and reinforce its facing layer. Such material is called "eurobrick" today.

What is it good for? Small width (2 times less than that of a standard stone) allows it to freeze less often. The adjacent wall transfers heat and thereby helps to stabilize the temperature of the cladding layer.

We conclude: when choosing a hollow facing brick, you must first of all pay attention to the thickness of its wall with the facing layer. The thicker it is, the more durable the stone.

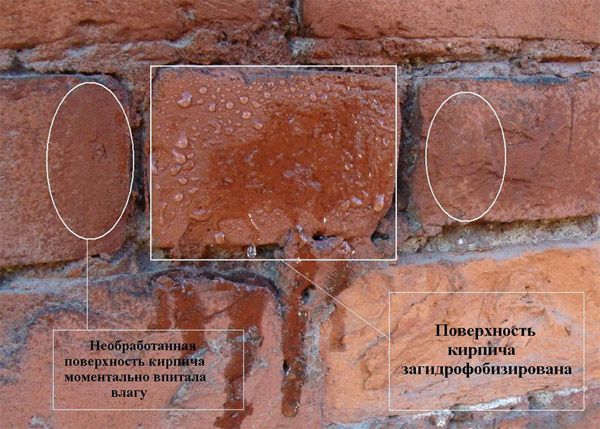

How to check the degree of water absorption of a brick when buying it

The information provided by the manager of a building materials store is not always true. The point is not in the seller's desire to deceive the buyer, but in the fact that he operates with data transmitted to him by the manufacturer.

A competent owner approaches the choice of building material extremely responsibly. He will definitely inquire about all the characteristics of the product declared by the manufacturer. For such a buyer, information on how to choose a facing brick according to the degree of water absorption will be useful.

It is necessary to put next to all those products that have been selected for comparison. A small amount of water is applied to each of them. You can use a spoon or any other suitable object for this purpose. Next, watch how quickly the building stones absorb water. Draw conclusions and make decisions. You can focus on the table.

Table. Moisture absorption of different types of facing bricks.

If possible, you need to find out if the front layer of the brick was treated with a water repellent at the factory. If yes, then it is necessary to clarify which one. Most modern water repellents are made on a paraffin basis. The surface treated by them has a water-repellent property. But at the same time with this plus, the product acquires two minuses at once.

- The vapor permeability of the face layer of the brick is reduced. Moisture that leaves the interior of a building through its outer walls meets a barrier - a layer of water repellent. For this reason, condensation builds up in the stone.

- The pores closed with paraffin prevent water from leaving the brick. Therefore, after laying stones on a cement-sand mortar, their moisture level increases significantly and remains so for a long time.

In addition to paraffin wax, there are imported water repellents based on chemicals. But due to their high cost, they are rarely used by brick manufacturers. Hydrophobization of facades is an important and necessary process. But it cannot be carried out in the first year after the completion of construction. It is necessary to wait until the stones are completely dry after laying.

Video - Facing brick for the facade. Which to choose?

Facade design options with facing bricks

Any project of a public or industrial building must include a detailed description of the facade design. Cladding bricks are often used by architects and designers to add personality to a building.

A private trader who has a built house can independently choose a finishing option and thereby realize his dream, and not other people's fantasies. In this difficult matter, information about the types of facing bricks and the most successful combinations of color and texture will provide serious help.

The main technique used to decorate facades is color highlighting.

There are two options:

- the use of a colored masonry mixture that contrasts or harmoniously matches the color of the facing brick;

- the use of building stones of different colors; in this way, you can emphasize the main lines of the building (arches, cornices, moldings) or highlight whole sectors.

There are many types of decorative masonry. Each of them is original in its own way and is able to decorate the building.

Highlighting in facade design

Types of facing bricks

When choosing a masonry pattern, you need to focus on the architectural style of the building. It should be noted that the fence, gate, entrance group of the house must form a single ensemble.

A frequently used technique for decorating facades is highlighting corners and window openings with color or texture.

Underline corners and window openings with color or texture

In this case, different types of brick dressing can be used, which creates an additional decorative effect.

Harmonious combinations of different types of masonry allow you to create a series of ornaments that make the appearance of the house unique.

If you use a facing brick with a rough texture, the house will acquire a deliberately brutal look.

Brick with a rough texture

The use of shaped bricks of different types and sizes allows you to build spectacular decorative lines. Facade design can be very different. A variety of colors, textures and types of facing bricks allows you to make your home beautiful and cozy.

Facing brick laying

Facade cladding technology is practically no different from the laying of ordinary ordinary bricks. Almost the same requirements are imposed on the process and quality of work. The difference is in the type of masonry and the type of binder used.

But finishing the facade with facing bricks is not an easy task. It requires masonry skills and knowledge of the nuances of working with each type of this facing material. In addition, the performer of the work must be extremely careful and perfectly master all the tools necessary for masonry.

Most often, in the process of facing facades, they use:

- trowel (the most convenient blade length is 18-19 cm);

- hammer pickaxe;

- mortar blade (for applying and distributing the binder over relatively large areas);

- jointing (necessary to give the masonry seams a beautiful shape);

- control devices (ordering, mooring lines, rule).

Types of facing masonry

For facades, the most spectacular types of brickwork are chosen.

- Track... In this type of masonry, each row consists of bricks laid with a "spoon" and is offset relative to the previous one by ½ or ¼ bricks.

- Blocky... It is carried out by alternating rows, in one of which the brick is laid with a "spoon", and in the next - with a "poke".

- Cross... It is a type of block masonry, but it is performed with an offset in every 2nd row by ½ brick. The result is a cruciform pattern, in which each "spoon" is surrounded by a single "poke" above and below.

- Gothic... One of the most difficult types of cladding masonry, which requires accurate brick displacement. Consists of alternating rows of spoons and pokes. In each next row, the "spoon" is shifted by ¼ of the length, and the "poke" by ½.

Facing technology

Step 1. Preparation for laying on mortar. Before placing the bricks on the mortar, always perform "dry" laying.

It is necessary in order to:

- determine the required number of building stones;

- pick them up in size and color;

- determine the required number of brick halves;

- determine the location of stones when making corners and openings.

During the placement of stones on the plinth, marks are made that will serve as a guide when laying on a mortar. At this stage of work, bricks are cut using a grinder equipped with a stone disc.

Step 2. Preparation of the solution. The mortar for facing brickwork differs from the standard one in that it is necessary to add only sifted, preferably river sand, to its composition. The proportions for the cement-sand mortar are standard: 1 part of Portland cement grade not lower than M400, 3 parts of sand, water, plasticizer, coloring pigment (if necessary). The consistency of the binder should be creamy. From a properly prepared solution, you can roll a soft ball.

Step 3. For laying the first row, perform the following actions:

- determine the highest point of the base;

- a reinforcing mesh is laid on the waterproofing coating;

- set, focusing on the marks made during the "dry" masonry, two corner bricks;

- pull a thread between them so that it indicates the height of the row;

- carry out the laying of intermediate bricks, making sure that the seam between them is of the same width (optimally 8-10 mm);

- in order for the brick to fall into place, it is knocked out with a pick;

- jointing is used to align and design the seams.

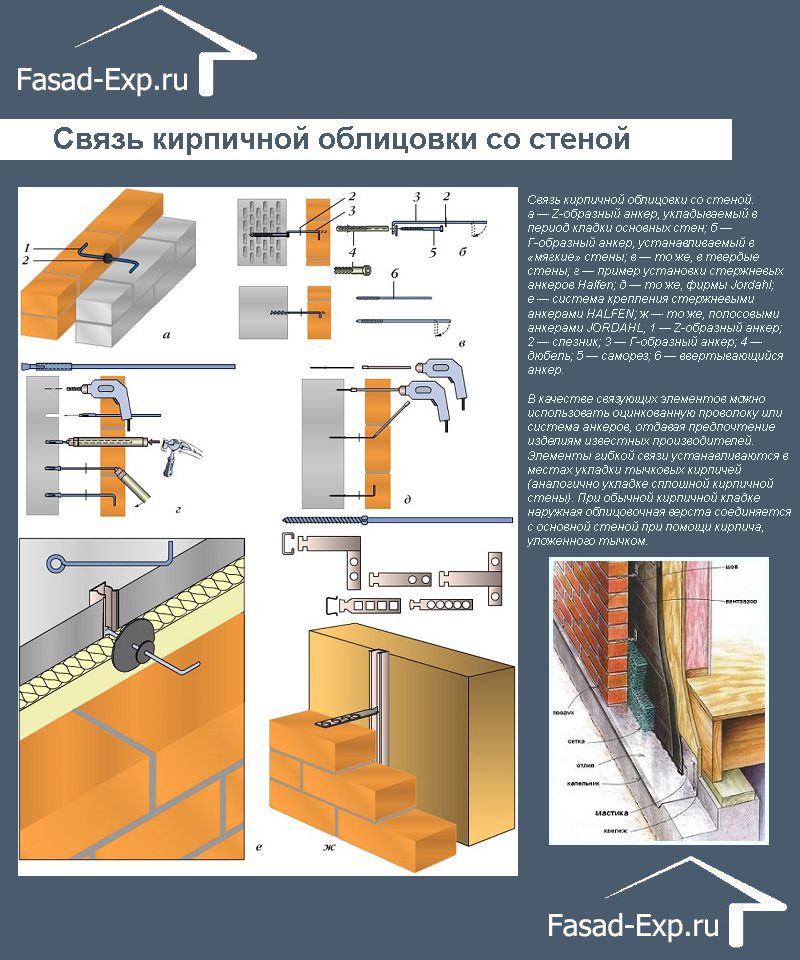

Step 4. Laying according to the pattern. To bandage the facing masonry with the bearing wall, use metal anchors, which are buried into the wall by at least 10 mm. Additional reinforcement of corners and openings with reinforcement rods is performed. The anchors are installed in brick increments of 2-2.5. The brick is laid in accordance with the masonry pattern.

When performing facing work, it is necessary to ensure that the cement-sand mortar does not stain the front surface of the building stones. If cement gets on it, it must be removed immediately with a dry cloth. Every 4-5 rows of facing masonry, the wall is wiped with a damp cloth.