The facade is the face of the building, and its appearance will depend on the correct choice of finishing material.

There are several types of cladding, and which ones we will consider in this article.

Varieties of finishes

Plaster

- is one of the oldest types of cladding. Its use belongs to one of the oldest types of cladding. What attracts it to itself, despite the laborious process of performing these works? Its advantage lies in excellent vapor permeability and a wide variety of textures. And also it can be combined with other types of finishes.

- Mineral plaster is distinguished by its durability and, with proper preparation of the walls, is able to retain its original appearance for many years. It is prepared from a cement-sand mixture with the addition of minerals and pigments to obtain various effects. The service life of such a facade is from 10 to 15 years.

- Acrylic plaster, due to its elasticity, makes cracks almost invisible.

Important: Acrylic plaster is not suitable for finishing with mineral wool insulation.

It can only be used with Styrofoam.

Also, this type of coverage is not recommended for houses located near roads.

The main disadvantage of this type of plaster is the difficulty in maintenance. The surface is clogged with dust, which is difficult to wash off. This in turn results in color loss. Its service life reaches 15 to 20 years.

- Silicate plaster, unlike acrylic, does not attract dust and is easy to clean, which means it retains its original appearance for many years. But it is also used only with foam insulation. The service life is 20 to 25 years.

In addition to the types we are accustomed to, there are new technologies in the decoration of facades, which make it possible to create cladding with an imitation of a stone or other texture.

Decorative rock

If you need a cheap facade finish, then this material is for you..

It appeared on the construction market relatively recently, but has already managed to fall in love with many builders.

- First, it has good thermal insulation.

- And secondly, it has a varied assortment of textures and shades.

Outwardly, it looks much more attractive than natural materials. And besides, it is lighter than natural stone. It is made of natural materials, and the highest quality dyes are used to give color, which do not fade over time.

The advantage is the prostate at work. In addition, it is the cheapest way to decorate the facade, in contrast to natural stone. Also, when working with it, you do not need to additionally prepare the walls of the building, which is important.

Facade panels

Facade panels have increased resistance to corrosion, provide additional heat and noise insulation, do not require preliminary surface preparation. They can be installed in any weather, but it should be noted that they are not very easy to install. Therefore, if you do not have the skills in this matter, it is more advisable to seek help from the masters.

Panel types

- Metal panels with polymer coating made of polyester are made of galvanized steel or aluminum. Aluminum panels are lightweight, while galvanized panels are heavier.

Their advantages: durable, withstand temperature changes, resistant to alkalis and acids.

Disadvantages: poor thermal insulation.

- Wood fiber panels. The material has good thermal insulation, and thanks to the protective layer with a wood grain texture it looks very nice.

Advantages: durable, easy to operate and install.

Disadvantages: Absorbs moisture, combustible.

- Facades with polymer facing is the most common method. These products are based on polyvinyl chloride (PVC), stabilizers and dyes.

Advantages: durability, fire resistance and low weight.

Disadvantages: afraid of frost.

Advice!

In order to avoid rusting during operation, the material should be fixed with aluminum nails.

- Facade panels made of polyurethane foam with the addition of marble chips in the form of blocks. Of the advantages, it is worth noting good soundproofing properties, resistance to decay, fungal diseases and mold. Not flammable.

- The sandwich panels will be made of several layers - two metal, a plastic and a vapor barrier layer. The only drawback of the panels is the possibility of freezing at the joints.

- Fiber cement boards. The material is 90% cement, and the remaining 10% is cellulose, filler and plastic. This type of material has many disadvantages. For example, low strength, after installation, painting is required and they are installed only on a metal frame.

Advantages: a large selection of imitation of various textures.

- Facade glass panels. An incredibly durable material that is resistant to burglary, impact, and even capable of withstanding gun shots. Accordingly, the price for it is much higher. It is widely used when finishing of facade windows is required.

- Front brick. There are many different colors and shapes, so you can create interesting finishes for all tastes. This product is strong enough and has good thermal insulation.

There are several types:- clinker,

- ceramic,

- silicate and,

- glazed.

Finishing with various materials

And how to decorate the facade of a building with your own hands, our instructions will help you.

Facade decoration with tiles

Cladding can be done in several ways.

The most famous is the installation of slabs to the wall using cement mortar.

- We take cement not lower than M 150 grade, mix it with sand, and dilute it with water, as indicated in the instructions on the package.

- To improve adhesion and plasticity, a PVA emulsion can be added to the water. it should be 7 to 10% of the volume of water. But this alone will not be enough for reliable fixation of the material, so we will also use anchoring devices, screws and screws.

- If you are using lightweight tile material, then it will be enough to build a frame from a metal profile.

- Before buying the finish you like, check with the sales consultant about its water absorption and frost resistance. The water absorption indicator should not be more than 8%, and the frost resistance indicator depends on the degree of water absorption, and must be from 25 thawing and freezing cycles. Otherwise, after 5-6 years, the finish will begin to deteriorate.

We decorate the facade with plastic and composite

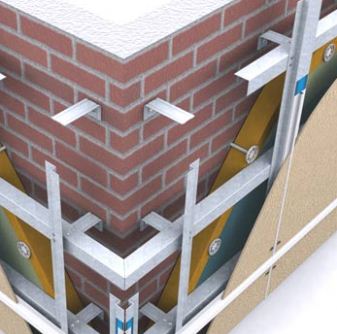

For this type of finish, it is necessary to use a ventilated facade structure.

To improve the heat-shielding qualities, we have to do the following work:

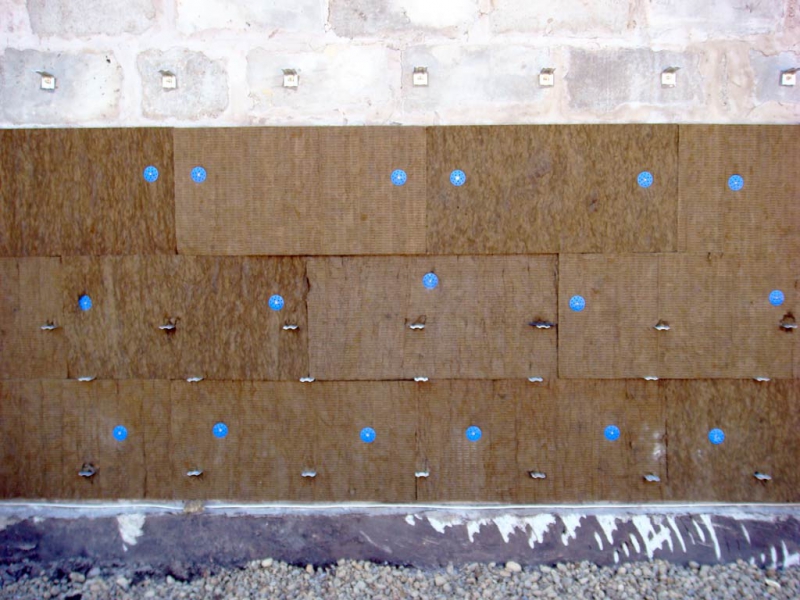

- We fasten the insulation with the help of plastic dowels to the wall of the building, as shown in the photo.

- The second layer is a waterproofing barrier film.

- And the third layer is cladding.

Moreover, it must be laid so that air can circulate freely in the gap between the coating and the insulation.

- When installing a ventilated facade, we attach the sheet facing material to the frame made of a bent galvanized profile. That is, we attach the CD profiles with a pitch of 40 to 60 cm to the building wall using direct suspension profiles in the vertical direction.

- Then we start laying the insulation and a special hydro-barrier film to protect the insulation from moisture. And we close all this with cladding.

We decorate the facade with plaster

Plastering is done as follows:

- Before you start plastering surfaces, you need to properly prepare the walls. Remove the layer of the previous finish and remove dust from the wall.

- If the walls are erected from cinder block, then we fasten the plaster metal mesh to the wall with brackets or nails.

- We process the wall with a layer of deep impregnation. Apply a contact primer to walls with poor adhesion.

Conclusion

Do-it-yourself facade decoration allows you to create a beautiful look for your home and at the same time save good money. And how professionals do it, you can see in the video in this article.