The best price for finishing the facade with bricks!

Facing the facade of the cottage with bricks - prices

Do you want to give the appearance of the cottage originality, but do not want to use siding, a fashionable block house or an expensive artificial stone for this? You can stay within the usual brickwork, but choose interesting colors and textures for the facade cladding, using the proposals of the facing brick manufacturers. Today, this material is present on the market of building and finishing materials in such a huge assortment that it is worthwhile to first familiarize yourself with the types, sizes, brands, configurations and design options for front surfaces available on the market.

The cost of finishing the facade with bricks. Price per m2

| Facade cladding area | Cost of work |

|---|---|

|

up to 50 m2 |

RUB 1,500 / m2 |

|

51 - 100 m2 |

1400 rubles / m2 |

|

101 - 200 m2 |

RUB 1300 / m2 |

|

201 - 300 m2 |

1200 rubles / m2 |

|

from 300 m2 |

RUB 1100 / m2 |

Types of facing bricks

By production technology distinguish between fired (ceramic) and non-fired (pressed concrete) facing brick. Already from the name it is clear that in the first case, the manufacturing process is based on sintering the components of the raw material at a high temperature, and in the second, the brick is obtained due to hydraulic binders - in most cases, this is Portland cement - and the pressure exerted on the workpiece in the mold. An exception is non-fired silicate bricks, the production process of which is based on the hardening of a lime-sand mixture during autoclaving.

To size There are three main types of facing bricks:

- Basic RF format, approved in particular for Russian manufacturers. Brick dimensions are 250 x 120 x 65mm;

- Western European format NF, which dictates the production of facing bricks with dimensions of 240 x 115 x 71mm;

- American format: the first two parameters are standard, and the end length is half or less.

This difference in size must be taken into account if you are going to combine facing bricks produced by two or more manufacturers in the facade cladding - during the masonry process, enormous difficulties may arise in adjusting products of different formats. It will not be easy to coordinate the layout of the facing brick with the geometry of the building itself.

Shaped face brick - a separate group of products that differ in shape and size. Most often, shaped bricks with rounded ends (one or both) or with corners cut at 45 degrees are used for facing facades. Other types of shaped bricks - for example, a triangular shape, with different lengths of ends, with a curly surface - should be purchased in full immediately or ordered from the manufacturer at the stage of designing a house. It is not recommended to introduce shaped bricks of a non-standard configuration without making sure that it is possible to purchase it in the required quantity + 10% for battle and marriage.

Decorative properties of facing bricks

Fired facing brick color ranges from creamy and yellowish to orange, bright red and even blackened. The specific shade of the products is dictated by the oxides of various metals contained in the feedstock, as well as by the sintering temperature and its duration. Ceramic bricks can differ in color even in one batch of a certain manufacturer, since the quantitative content of impurities depends only on the deposit from which the clay is mined. In order to maintain a uniform color scheme of the walls, the brick should be mixed during the cladding process - taken from different packs.

Hyper-pressed brick color varies in a wide range of colors and is uniform in every batch. Coloring occurs due to the introduction of mineral additives and pigments into the composition of the raw material, giving the surface of the product the required shade. The color of such bricks, in contrast to fired bricks, does not differ in particular brightness.

Face brick surface can be smooth or grooved. A special relief is formed due to the arbitrary alternation of protrusions and depressions. The "Rock" brick with a chipped surface is very well known. This is a type of hyper-pressed brick that actually splits in half after being removed from the mold. It looks beautiful, resembling a natural rock surface, but it is not recommended to use it to decorate the entire facade, since at the moment of splitting, a mass of microcracks forms in the product, which will certainly make themselves felt after several cycles of freezing and thawing. However, in places protected from moisture, it is quite reliable. A wide variety of reliefs are rolled onto fired bricks, while the brick does not lose its strength and durability.

Engobing and glazing of bricks - technologies for applying a colored layer to the finished brick. In the first case, this is spraying an already dry product with solutions with a high pigment content, as a result of which a spray of a certain intensity appears on the surface. In the second, a continuous layer of decorative glaze is applied, followed by the formation of a durable glassy coating.

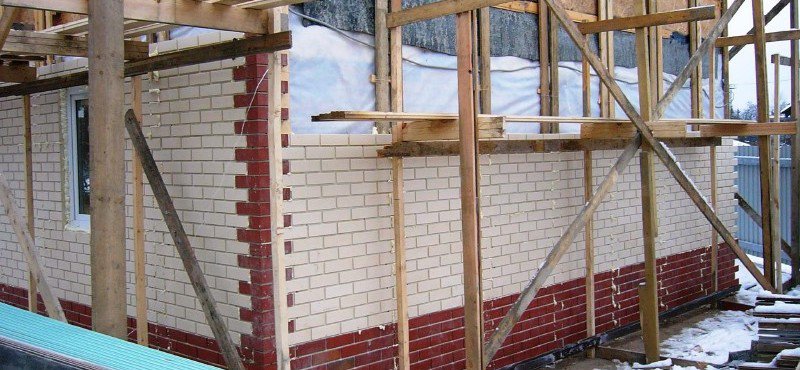

Facing brick laying

There are many ways to lay facing bricks, each of which creates its own pattern on the surface of the facade. The most famous are “track” (long side), “block” (row with long side, row with short side), “cross” (repeats the previous version, but with displacement of the joints by ½ the length through the row); "gothic" (alternating with offset).

But the technology for making brickwork on the facade is common. The main rule is accuracy. Before proceeding with the laying of bricks on the mortar itself, they perform its dry version, determining the total number of bricks, the number of bricks that need to be trimmed, selecting material for the design of openings, removing marriage and battle. The cutting of bricks of non-standard length is performed with a grinder using a stone disc. Chipping off a part of a brick with a hammer is not allowed.

The mortar for laying facing bricks is prepared in the ratio of 3 parts of sifted river sand / 1 part of Portland cement / 1 part of water. The composition dries quickly, therefore it must be prepared in small quantities, and the brick itself must be moistened with water immediately before use. This will allow for a gradual setting of the mortar and, as a result, more durable seams. The thickness of the horizontal seam can be up to 12mm, for the vertical one it should not exceed 10mm. To ensure ventilation of the facade, every fourth vertical seam in the bottom row is left without mortar. The facing layer is tied to the main wall with anchors (diameter 4-6 mm) and wire, which is laid in the seams. There should be 45 attachment points per square meter of masonry.

When working with colored facing bricks, tint additives for mortar are used - in tone or contrasting. They help to get a complete harmonious picture of the facade. The solution that gets on the front part of the facade during the masonry process must be removed in a timely manner. When the cement has set, the seams are sutured, pressing the mortar inward. Thus, they achieve a more durable bond between the bricks and improve the aesthetics of the joints and the surface as a whole.