Facades made of facing bricks invariably attract admiring glances. Every developer knows that it is not enough to build strong walls. They need to be finished with such material that it helps to immediately get a triple benefit: it insulates, strengthens and decorates the building. These requirements are fully met by facing bricks. It is able to reliably protect external walls and increase their bearing capacity.

A special type are the so-called Clinker bricks, which have the lowest absorption and are characteristic of their bells. Another widespread use of facing bricks in the form of tiles is shingles. Tiled strips are an easier way to achieve the look of a brick façade. They are especially used when the bricks can no longer be used for technological reasons or during repairs. They are an excellent option for surface treatment of thermal insulation systems.

They are made by cutting bricks, so they are the same as bricks. In the range of unique brick products, we should not forget about brickwork. It's as fake as it is frostproof, making it perfect for patios, paths, driveways. High durability is another one of their countless features, making it suitable for running surfaces, driveways and garages. Brick laying is colored and resistant to adverse climatic conditions. The pavement is glued to a mortar or placed in sand.

- facing;

- facade;

- facial.

All this is the same material that has the properties necessary for high-quality finishing of the building. The outer layer of the wall is built from these stones, which is in direct contact with the environment and experiences all its adverse effects. Therefore, to technical specifications these products are subject to special requirements.

When laid in a sandy layer, water can easily flow through the subsoil and the tiles remain collapsible. Here, too, don't be afraid of color fading, as is the case with a concrete walkway, so you can enjoy life on your patio or sidewalk. The front of the house is one of the most crowded places in the entire building. Repeated exposure to wind, rain, snow, temperature fluctuations and chemicals. That is why we need to take into account all the possibilities for its correction that today offers us.

Liquefied brick is a purely natural material, which is formed by a combination of the main natural elements, namely earth, water, air and fire. At the beginning of the second millennium, the popularity of brick masonry materials as visible masonry is growing. For many people, brick on the exterior façade is synonymous with the high standard of a home. However, the decision to use it as a building block for all exterior walls cannot be accidental. It must take into account the architecture of the building, its incorporation into the landscape and its connection with tradition.

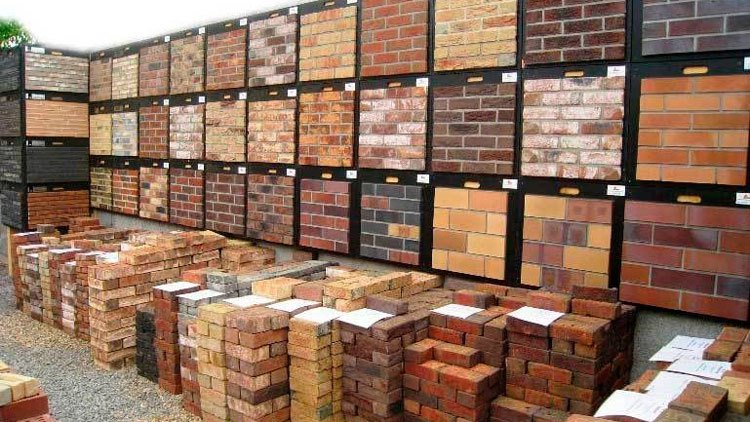

Depending on the type of materials used in the manufacture and the method of production, several types of facing bricks are distinguished:

- clinker;

- ceramic;

- hyperpressed;

- silicate.

These products have different performance characteristics, but there is one thing in common: they can all have a traditional parallelepiped or curly shape. Bricks of the second type are called shaped. Each of the options has its own production standards, which all manufacturers adhere to.

In Silesia, Pomerania or Masuria, where brick houses have been inserted into environment, brick facades look good. On the contrary, when other materials dominate, they can cause dissonance. A safer solution is to use bricks on the facade details or finish the workpiece. The house looks solid and at the same time not as heavy as a brick. Even the small details of the brick give the impression that the house is rooted and tied to its environment. The same material can also be used to maneuver fences, lawns, or debris.

Bricks of the traditional form are:

- single;

- one and a half;

- thickened;

- double.

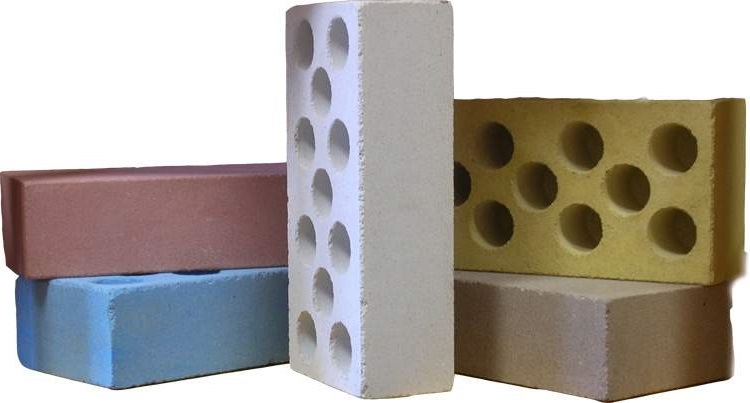

Each of the listed products can be solid or hollow (hollow). Stones of the second type may have different shape holes and their number.

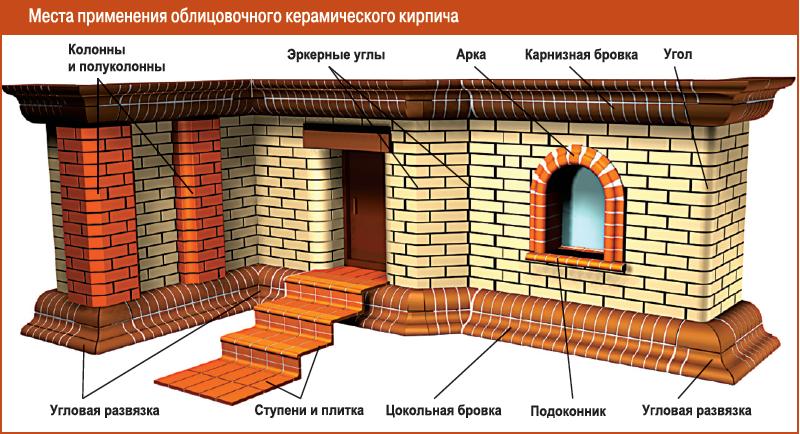

Where to place the external facade for the installation of brick details?

Most often, brick is used in the ground floor, as a material that looks optically heavier. The top floor is usually finished with plaster or wooden blinds. In this way, you can get an optical loft compartment, which makes the house look lighter and lower than it really is. Brick works well in dirt-prone areas such as a plinth, chimney, stairs, poles, or pantry - on a gable wall with no eaves or sill.

A very practical and long-awaited solution is the use of brick in the form of a plinth, that is, the lower strip of the facade. The manufacture of bricks will certainly be associated with strength and durability. Not only does it protect the wall from moisture and dirt, but it can also be a great tool for shaping the body of a building because you can use it to change the scale and proportions of a house or highlight a piece. The effect depends on its height, shape, color, location and connections with other elements and facade details.

Shaped bricks impress with their spectacular appearance. With the help of these building stones, you can realize the most original ideas of architects and designers.

Manufacturers offer shaped bricks of the following types:

- trapezoidal shape with beveled ribs;

- twisted;

- wedge-shaped;

- with a textured front surface (under the chipped or natural stone).

Spectacular appearance figured stones largely depends on the method of decorative processing of their surfaces.

It will become light when we apply brightly colored bricks. Such characters most often occupy plots in houses without basements with traditional architecture. A tall, sleek brick pedestal looks great on spacious bungalows. In modern buildings, plinth, plastered, is often used to build terrace walls. The brick entrance area will make the house a worthy, trusting character. Bringing brick from a building, such as bay windows, ribs, pillars or corners, can be used to exaggerate the wealth of a home.

Brick details on the facades of the facades on the upper floors

Antique brick adds patina to new house and well connected with the top stone. It was used on objects especially vulnerable to damage - pedestals, columns, corners and around front door. Even small brick elements such as window sills and window sills will greatly increase the height. To brighten up a simple home without overpowering it, you can also opt for brick window frames or cornices. Molded cornices create the effect of separating the floor - the plastered wall strip of ready-made bricks is also clearly marked.

Three technologies are used:

- glazing;

- shotting;

- engobing.

For facing the facade of a residential building, engobed bricks are more suitable. They have a matte surface and, due to the production method, have a lower coefficient of thermal conductivity. The engobing technology involves applying an additional layer of clay to the raw stone. It is he who makes the product more “warm”.

They can be used to emphasize the structure of a building or divide a front wall in the past. The emphasis on the division of the floors is served by cordon cornices. Rarely, brick is used as a crown frame, or crown building. A brick cornice with rich decorative systems, such as a brick frieze contrasting with plastered peaks, may be the only decoration of a wall. Brick details can also emphasize the axis of the building. Very often this lisen function is complete, i.e. flat ledges on the facade.

Brick facade not only in Masuria

In particular, façade brickwork is often a frame that emphasizes the shape of the window or door or the material it was made from. Such structures are deeply rooted in many regions of the country. Like a lintel, it is a structural element that carries the weight of the wall fragment directly above the window. Bricks in the lintel can be laid different ways- straight, wedge or vaulted. Since the first two are quite simple, lintel arches require more work and a good performer.

Engobed bricks

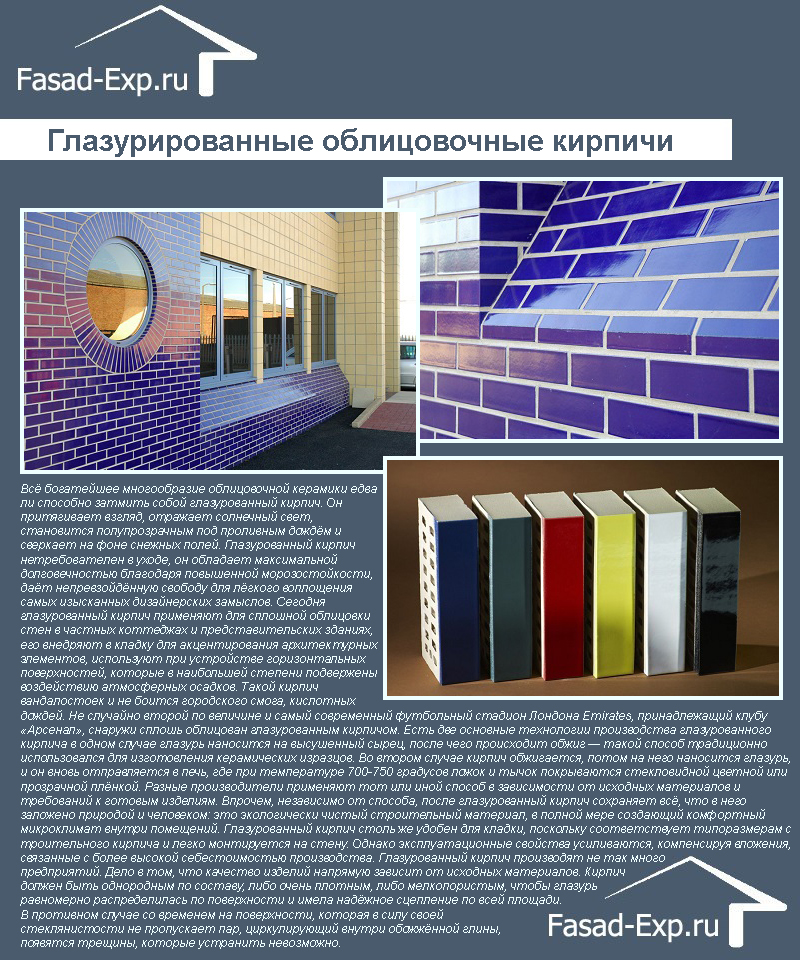

Glazed bricks have a glossy surface. The color range of such stones is very wide. Glazing can be applied in two ways: on the raw or finished product. Regardless of the technique, the quality and appearance of the product will be the same.

The most common are semi-circular arches and flatter point arches, which are a segment of a circle with a diameter larger than the aisle. The shape of the lintel often reflected the position of the homeowners. For example, in wealthy Masurian houses the lintels were formed like a brick of bricks, while in the poorer ones they were arranged in a straight line.

In addition, window sills can be a beautiful element in decorating exterior walls. Of the bricks are thick, which give the facade a massive look. It does not look like a traditional lightweight window sill, but forms a decorative and durable window base and at the same time easily covers its composition.

Torqueting is the process of applying mineral chips to the front surface of a brick. After firing, the product acquires a beautiful relief texture. These stones are often used to highlight architectural elements buildings: arches, entrance group, window openings, cornices.

Quite balustrades often make the impression too heavy, so a mixed rail is a good solution. Here, the brick cladding façade is also used for the balustrade, which is combined with wood elements to add lightness. This is also due to the bright colors - honey and yellow brick.

Various shades and textures of brick details on external facades

The appearance and details of the details of the facade and its relationship with other elements of the facade are largely determined by the color and texture of the brick. Several colors allow you to choose a brick for each solid. Traditionally, the brick and mortar tradition is most often used in the details of traditional houses. Paired with a red tile roof on a gable roof, and white or natural wood windows frame the home's deeply rooted image.

Ceramic brick shotcrete with mineral chips.

Pros and cons of clinker bricks

Clinker - one of the best representatives of facing bricks. Such interdependent characteristics as water absorption and frost resistance are at their best. These stones are able to withstand up to 300 freeze-thaw cycles (frost resistance factor F300). But the thermal conductivity is quite high: 0.7 W / (m * ° C). Durability - at least 100 years.

The warm reddish color also emphasizes the beauty of the plant and enlivens the environment at any time of the year, so the brick in this tone will look like finishing details of houses surrounded by greenery. Successfully enjoyed yellow shades. They go well with white stucco, they are an interesting decoration for modern houses, referring to modernist traditions - they are used as the finish of cornices or elevation fragments.

Bricks in a shady rich discoloration, reminiscent of the shimmering melange of tweed fabric, are the perfect material for a rustic country house, manor house, well combined with rough plaster. It's worth using it on a piece of wall that you can touch and look at closely. A good piece of house made of gypsum in intense color is white brick - from it - a door frame or a window to calm the living facade. Dark bricks - in shades of brown, garnet or black - are best perceived as cladding small elements of the external facade - are used in the vast majority.

Among the features of this material is the duration of its masonry. This is due to the low water absorption coefficient. The stone slowly absorbs moisture from the solution, so working with it requires a certain skill.

The disadvantages of this material include the fact that even in one batch of clinker bricks there are often products different shade. This greatly complicates the masonry process and increases the construction time. Workers have to choose stones that are identical in color and most beautifully distribute those with a darker shade on the wall.

Brick facade is beauty and style

varied texture facade brick provides excellent layout options. You can apply traditional smooth - shiny or matte. They create a neat, clean composition on the wall. However, brickwork, sandblasting, and hand-moulded stylized items are becoming increasingly popular. They imitate those affected by time and atmospheric conditions. Their irregular surface deviates from the schematic repetitions of pseudocracks and isosceles. An old, worn out brick reminds me of an illusion.

Clinker brick requires laying on special mortars. The cost of these compounds is high, as is the price of the material itself. There is the possibility of laying on a cement-sand mortar, but you need to know the recipe for preparing the mixture and be able to work with it. On a normal mortar, the clinker brick "floats".

Pros and cons of ceramic facing bricks

Ceramic bricks are distinguished by a variety of shapes and colors. The undoubted advantage of these products is environmental friendliness. At first glance, these stones look fragile due to the large number of voids. But this is a misleading impression. Ceramic bricks are highly durable.

They look good, especially when combined with traditional natural materials- wood, ceramic tiles, straw or pebbles. Brick details are best presented in combination with plaster in soft pastel colors that are inherent in nature and home. He also likes fashionable with a trendy wooden face. The colorful variety of bricks allows you to compose wood of any color.

Text: Hanna Jankowska Publication title: Build a house. Plaster is the most popular way to finish the facade. This is not the only one who can give style, emphasize the character of domestic architecture, express individuality and diversify areas. These features deserve special attention, for example with the help of lining.

The main disadvantage of these stones is the errors in the geometry of the shape. This complicates the masonry process, as it is necessary to check the conformity of the sizes of the stones. Another drawback is limestone inclusions, which subsequently absorb moisture and begin to stand out on the wall surface with their more saturated color.

Finishing the facade of the house is not only aesthetics, but also the most aesthetic, which is most often received and appreciated. And for that matter, a way to finish it. The most popular - plastering - does not limit the use of other methods, for example, when repairing or updating, and also when a new house and after plastering we came to the conclusion that the facade has become boring, does not emphasize its important architectural elements. In such situations, you can always reach the wall tiles or facade. Their common features are ease of installation on the facade, perfect fit of the selected collection, durability and a set of manufacturer's materials necessary for installation and maintenance.

Pros and cons of hyper-pressed brick

The composition of hyperpressed brick includes shell rock, cement, special additives.

Advantages of this type of stones:

- perfectly even geometric shape;

- the same dimensions of all products of the same type;

- variety of colors;

- malleability in processing (easy to cut);

- high strength 150-300 kg/cm2;

- water absorption 5-6%;

- frost resistance F150;

- a wide range of shaped models.

Hyperpressed brick has practically no drawbacks. The disadvantages include big weight(4.2-4.4 kg), which affects the cost of transportation and the complexity of masonry.

Pros and cons of silicate facing bricks

Silicate brick is distinguished by regularity of forms and high strength. Among the advantages of this facing material is the ability to withstand high temperatures, ease of processing, high soundproofing characteristics, reasonable price.

Flaws:

- high thermal conductivity, which increases with moisture;

- large weight (single 3.3-3.6 kg, one and a half - 4-4.3 kg);

- uniformity of colors;

- high coefficient of moisture absorption;

- lack of shaped models.

Should I buy a hollow facade brick?

The peculiarity of most affordable stones of this type is that they have the maximum possible number of voids. This is due to the peculiarities of manufacturing technology and the desire of manufacturers to save money. For the same purpose, they (manufacturers) often make only two edges of the product face: one spoon and one poke. But such a decision is justified, since the stone is turned outward with only one of its sides. The size and shape of the voids can be different, respectively, the weight of the bricks is also different.

The facing layer is usually thin. Since behind it is a porous structure stone with many voids, the front layer does not receive enough heat from it and is often supercooled. This leads to the appearance of microcracks. Water penetrates into them, which periodically freezes and thaws. The wind and the rays of the sun contribute to the process of destruction. All this leads to sad consequences for the building. Therefore, one can often see facades, the front brick of which is partially destroyed.

The disadvantage of such building stones was first understood by the Europeans. They decided to halve the width of the product and strengthen its facing layer. Such material is today called "eurobrick".

Why is he good? A small width (2 times less than that of a standard stone) allows it to freeze less often. The adjacent wall transfers heat and thus helps to stabilize the temperature of the facing layer.

We conclude: when choosing a hollow facing brick, it is necessary, first of all, to pay attention to the thickness of its wall with the front layer. The thicker it is, the more durable the stone.

How to check the degree of water absorption of a brick when buying it

Not always the information reported by the manager of the building materials store is true. The point is not in the seller's desire to deceive the buyer, but in the fact that he operates with the data transmitted to him by the manufacturer.

A competent owner approaches the choice building material extremely responsible. He will definitely ask about all the characteristics of the product declared by the manufacturer. For such a buyer, information on how to choose a facing brick according to the degree of water absorption will be useful.

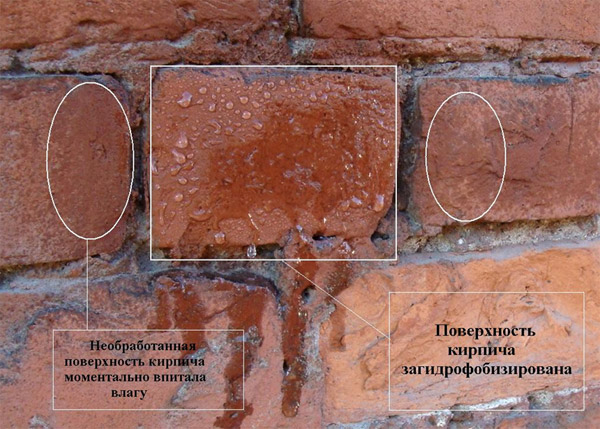

It is necessary to put next to all those products that were selected for comparison. A small amount of water is applied to each of them. You can use a spoon or any other object suitable for this purpose. Next, observe how quickly the building stones absorb water. Draw conclusions and make decisions. You can refer to the table.

Table. moisture absorption different types facing brick.

If possible, you need to find out if the face layer of the brick was treated with a water repellent at the factory. If yes, then you need to specify which ones. Most modern water repellents are made on a paraffin basis. The surface treated by them has a water-repellent property. But at the same time with this plus, the product immediately acquires two minuses.

- The vapor permeability of the face layer of the brick is reduced. Moisture that comes out of the interior of the building through its outer walls meets an obstacle - a layer of water repellent. For this reason, condensation accumulates in the stone.

- The pores closed with paraffin do not allow water to leave the brick. Therefore, after laying stones on a cement-sand mortar, their moisture level rises significantly and remains so for a long time.

In addition to paraffin, there are imported water repellents made on the basis of chemicals. But due to the high cost, they are rarely used by brick manufacturers. Facade hydrophobization is an important and necessary process. But it cannot be carried out in the first year after the completion of construction. It is necessary to wait until the stones are completely dry after laying.

Video - Facing brick for the facade. Which to choose?

Options for decorating facades with facing bricks

Any project of a public or industrial building must include a detailed description of the facade device. Architects and designers often use facing bricks to add personality to a building.

A private owner who has a built house can independently choose the finishing option and thereby realize his dream, and not other people's fantasies. In this difficult matter, information about the types of facing brick masonry and the most successful combinations of color and texture will be of great help.

The main technique that is used to design facades is highlighting with color.

There are two options:

- the use of a colored masonry mixture that contrasts or harmoniously combines with the color of the facing brick;

- the use of building stones of different colors; in this way, you can emphasize the main lines of the building (arches, cornices, moldings) or highlight entire sectors.

There are many ways to decorate masonry. Each of them is original in its own way and is able to decorate the building.

Highlighting color in the design of facades

Types of facing brick masonry

When choosing a masonry pattern, you need to focus on the architectural style of the building. It should be noted that the fence, gate, entrance group of the house should form a single ensemble.

A frequently used technique for decorating facades is to emphasize corners and window openings with color or texture.

Underlining the color or texture of corners and window openings

In this case, different types of brick ligation can be used, which creates an additional decorative effect.

Harmonious combinations various kinds masonry allows you to create a series of ornaments that make the look of the house unique.

If you use a facing brick with a rough texture, the house will take on a deliberately brutal look.

Brick with a rough texture

The use of shaped bricks different type and size allows you to build spectacular decorative lines. Facade design can be very different. A variety of colors, textures and types of facing bricks allows you to make the house beautiful and cozy.

Facing brick laying

The technology of facade cladding is practically no different from the laying of ordinary ordinary bricks. Almost the same requirements are imposed on the process and quality of work. The difference is in the type of masonry and the type of binder used.

But finishing the facade with facing bricks is not an easy task. It requires masonry skills and knowledge of the nuances of working with each type of this facing material. In addition, the performer of the work must be extremely accurate and be fluent in all the tools necessary for masonry.

Most often in the process of facing facades use:

- trowel (the most convenient blade length is 18-19 cm);

- hammer-pick;

- mortar blade (for applying and distributing a binder over relatively large areas);

- jointing (necessary to give the masonry seams a beautiful shape);

- devices for control (ordering, mooring cords, rules).

Types of facing masonry

For finishing facades, the most spectacular types of brickwork are chosen.

- Track. In this type of masonry, each row consists of bricks laid in a “spoon” and is offset from the previous one by ½ or ¼ bricks.

- block. It is carried out by alternating rows, in one of which the brick is laid with a “spoon”, and in the next - with a “poke”.

- cross. It is a type of block masonry, but is performed with an offset in every 2nd row by ½ brick. The result is a cruciform pattern in which each "spoon" is surrounded by a single "poke" at the top and bottom.

- gothic. One of complex types facing masonry, which requires the accuracy of displacement of bricks. Consists of alternating rows of "spoons" and "pokes". In each next row, the “spoon” is shifted by ¼ of the length, and the “poke” by ½.

![]()

Cladding technology

Step 1. Preparation for laying on the mortar. Before laying the bricks on the mortar, always perform a “dry” laying.

It is necessary in order to:

- determine the required number of building stones;

- choose them by size and color;

- define right amount halves of a brick;

- determine the location of stones when making corners and openings.

During the placement of stones on the base, marks are made that will serve as a guide when laying on the mortar. At this stage of work, bricks are cut using a grinder equipped with a stone disc.

Step 2 Solution preparation. The mortar for facing brick laying differs from the standard one in that only sifted, preferably river sand, must be added to its composition. The proportions for the cement-sand mortar are standard: 1 part Portland cement grade not lower than M400, 3 parts sand, water, plasticizer, coloring pigment (if necessary). The consistency of the binder should be creamy. From a properly prepared solution, you can roll a soft ball.

Step 3 For laying the first row, perform the following steps:

- determine the highest point of the base;

- a reinforcing mesh is laid on the waterproofing coating;

- install, focusing on the marks made during the "dry" masonry, two corner bricks;

- pull a thread between them so that it indicates the height of the row;

- perform laying of intermediate bricks, making sure that the seam between them is of the same width (optimally 8-10 mm);

- in order for the brick to fall into place, it is knocked out with a pick;

- stitching is used to align and decorate the seams.

Step 4 Masonry according to the drawing. For ligation of facing masonry with a bearing wall, metal anchors are used, which are deepened into the wall by at least 10 mm. Perform additional reinforcement of corners and openings with reinforcement rods. Anchors are installed in increments of 2-2.5 bricks. The brick is laid in accordance with the masonry pattern.

When performing facing work, it is necessary to ensure that the cement-sand mortar does not stain the front surface of the building stones. If cement gets on it, it must be immediately removed with a dry rag. Every 4-5 rows of facing masonry, the wall is wiped with a damp cloth.

Video - Brick cladding